Linear guides are the backbone of modern industrial machinery, enabling precise, repeatable linear motion in a wide range of applications. From 3D printing to robotics and automated systems, these components play a critical role in ensuring efficiency, durability, and reliability. As a leading manufacturer and supplier of high-performance linear guides, we understand the importance of selecting the right solution for your specific needs. In this article, we’ll explore the fundamentals of linear guides, their applications, customization options, and maintenance best practices to help you make informed decisions for your projects.

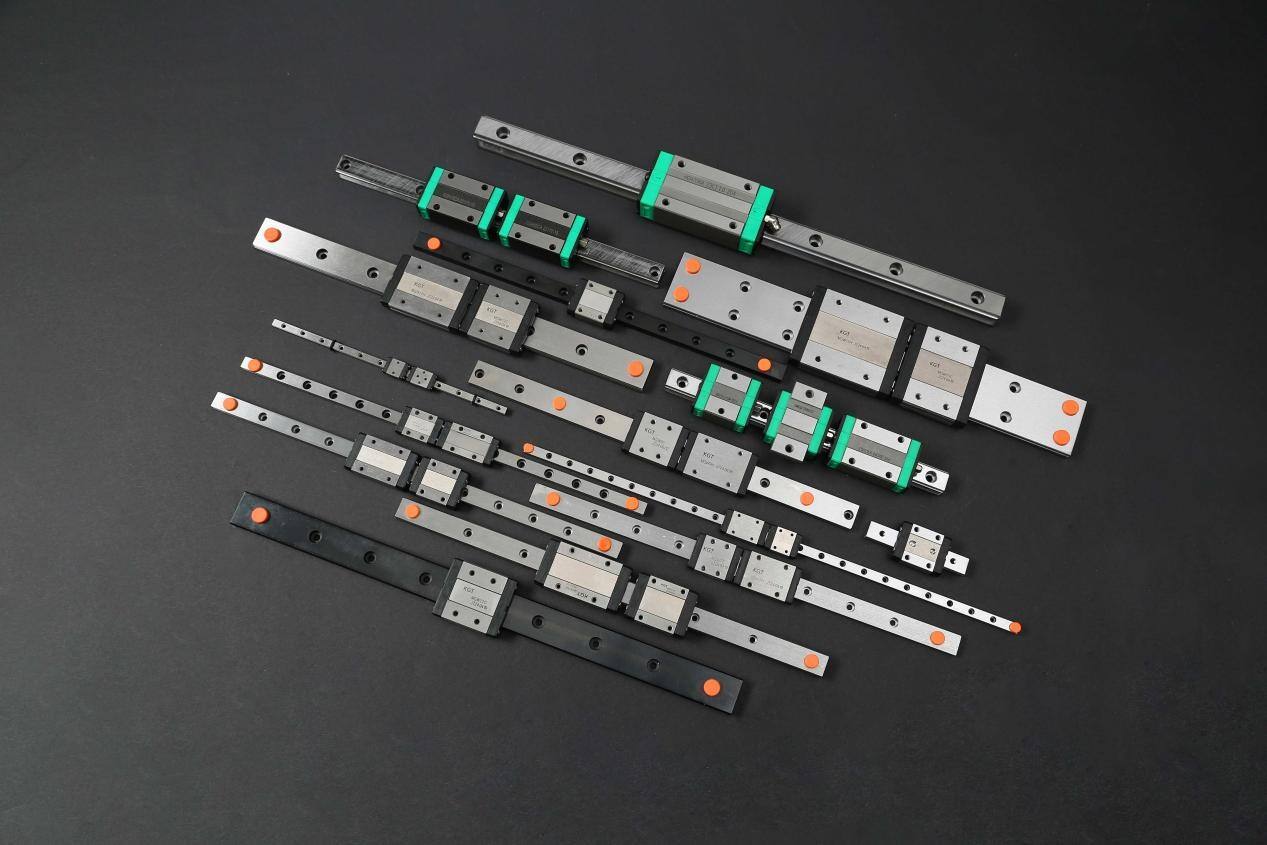

A linear guide is a mechanical system designed to facilitate high-precision linear motion by combining a sliding block (carriage), a rail, and a recirculating ball mechanism. This design allows for smooth, low-friction movement, making it ideal for applications requiring exact positioning and heavy-load capacity. The core components of a linear guide include:

- Rail: A hardened steel or stainless steel track that provides structural support and alignment.

- Carriage: A movable block that slides along the rail, often equipped with ball bearings or roller bearings for reduced friction.

- Recirculating Ball Mechanism: A closed-loop system that ensures continuous motion by guiding balls between the rail and carriage.

Linear guides are also known as linear motion rails or*linear bearings, and they are engineered to withstand demanding environments while maintaining micron-level precision. Their ability to handle both radial and axial loads makes them indispensable in industries such as manufacturing, automation, and robotics.

The versatility of linear guides stems from their exceptional hardness, high-speed capabilities, and precision. Below are some of the most common applications:

1. 3D Printing

In 3D printers, linear guides ensure accurate layer-by-layer movement of the print head or build platform. High-precision linear motion is essential for achieving detailed, high-quality prints.

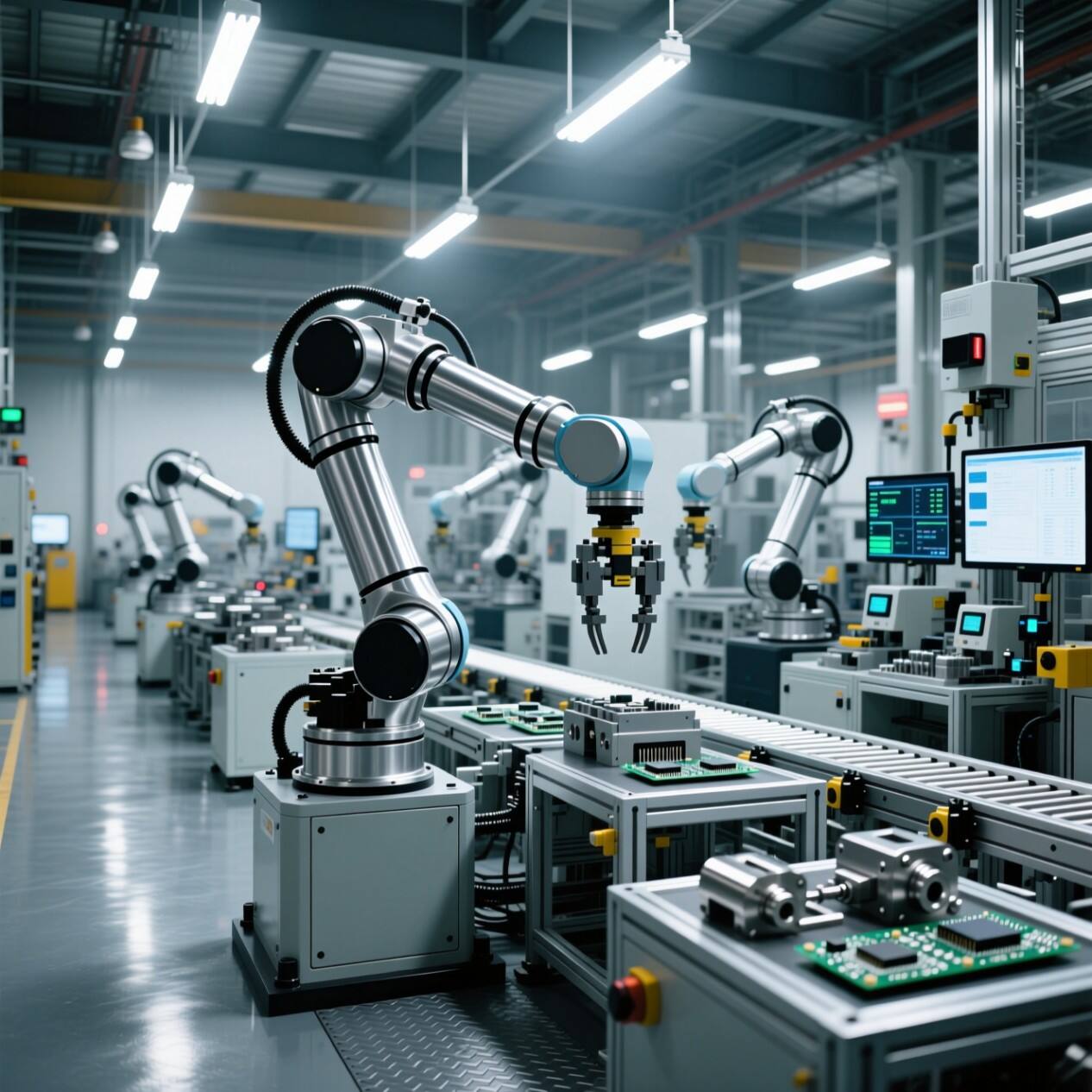

2. Robotics

Robotic arms and automated systems rely on linear guides for smooth, repeatable motion. Whether in assembly lines or collaborative robots (cobots), these components enable precise positioning and rapid movement.

3. Automated Machine Tools

CNC machines and milling centers use linear guides to maintain dimensional accuracy during high-speed operations. Their low-friction design reduces wear and extends tool life.

4. Electric Doors and Gates

Linear guides are used in automated access control system, such as electric doors and gates, to ensure smooth, noiseless operation.

5. Precision Machinery

Industries like semiconductor manufacturing and medical device production depend on linear guides for micron-level precision in critical processes.

Selecting the optimal linear guide involves evaluating key factors such as load capacity, speed requirements, and environmental conditions. Here’s a step-by-step approach to streamline your decision-making process:

Step 1: Define Application Requirements

- Load Capacity: Determine the maximum static and dynamic loads your system will experience.

- Speed and Acceleration: High-speed applications may require low-friction materials or lubrication systems.

- Environmental Conditions: Consider temperature, humidity, and exposure to dust or chemicals.

Step 2: Leverage Expert Support

Our team of engineers offers real-time online consultation to help you choose the best linear guide for your project. Whether you need standard models or specialized solutions, we provide technical documentation, including 3D CAD files, datasheets, and load charts.

Step 3: Global Delivery and Customization

With five strategically located overseas warehouses, we ensure fast delivery to clients worldwide. For custom requirements, we offer OEM/ODM services, including:

- Material Upgrades: Options for stainless steel, corrosion-resistant coatings, or high-temperature alloys.

- Dimensional Adjustments: Tailored lengths, widths, and mounting configurations.

- Integrated Lubrication Systems: Pre-lubricated models or self-lubricating variants for maintenance-free operation.

If customization is required, we provide detailed technical specifications via email, including product labels, drawings, and performance parameters. This ensures seamless integration into your existing systems.

Proper installation and regular maintenance are essential to maximize the lifespan and performance of linear guides.

Installation Process

1. Mounting the Rail: Secure the rail to a rigid base using high-strength fasteners. Ensure the rail is perfectly aligned to avoid binding or uneven wear.

2. Carriage Assembly: Attach the carriage to the moving component (e.g., a robotic arm or conveyor belt). Verify that the carriage aligns with the rail’s grooves.

3. Testing: Run a trial operation to check for smooth motion and adjust tension or alignment if necessary.

Maintenance Tips

- Lubrication: Use high-quality grease or oil lubricants based on operating conditions. Grease is ideal for high-load applications, while oil is better for high-speed operations. Reapply lubrication every 500–1,000 operating hours.

- Cleaning: Regularly remove debris and contaminants using compressed air or soft brushes to prevent premature wear.

- Inspection: Check for signs of wear, misalignment, or corrosion. Replace components if damage is detected.

By following these guidelines, you can ensure long-term reliability and optimal performance of your linear guides.

We specialize in delivering industrial-grade linear guides that combine innovation with proven reliability. Here’s what sets us apart:

1. Superior Quality and Precision

Our linear guides are manufactured using high-carbon steel and heat-treated surfaces to enhance durability. With tolerances as tight as ±0.001mm.

2. Fast Delivery

We reduce lead times and ensure cost-effective logistics. Our 24/7 technical support team is available to assist with product selection, installation, and troubleshooting.

3. Customization Expertise

We offer end-to-end customization services, from prototyping to mass production. Whether you need a unique rail profile or a custom lubrication system, our engineers work closely with you to meet exact specifications.

4. Cost-Effective Solutions

Our competitive pricing, combined with bulk order discounts and volume-based shipping rates, ensures you get the best value without compromising quality.

Choosing the right linear guide is a strategic decision that impacts the performance and longevity of your machinery. By understanding their working principles, applications, and maintenance requirements, you can optimize your systems for precision and efficiency. With our global delivery network, customization capabilities, and technical expertise, we are committed to providing solutions that meet the demands of modern industry.

Ready to upgrade your systems? Contact our team today for a personalized consultation or request a sample. Visit our website to explore our full product range and technical resources.