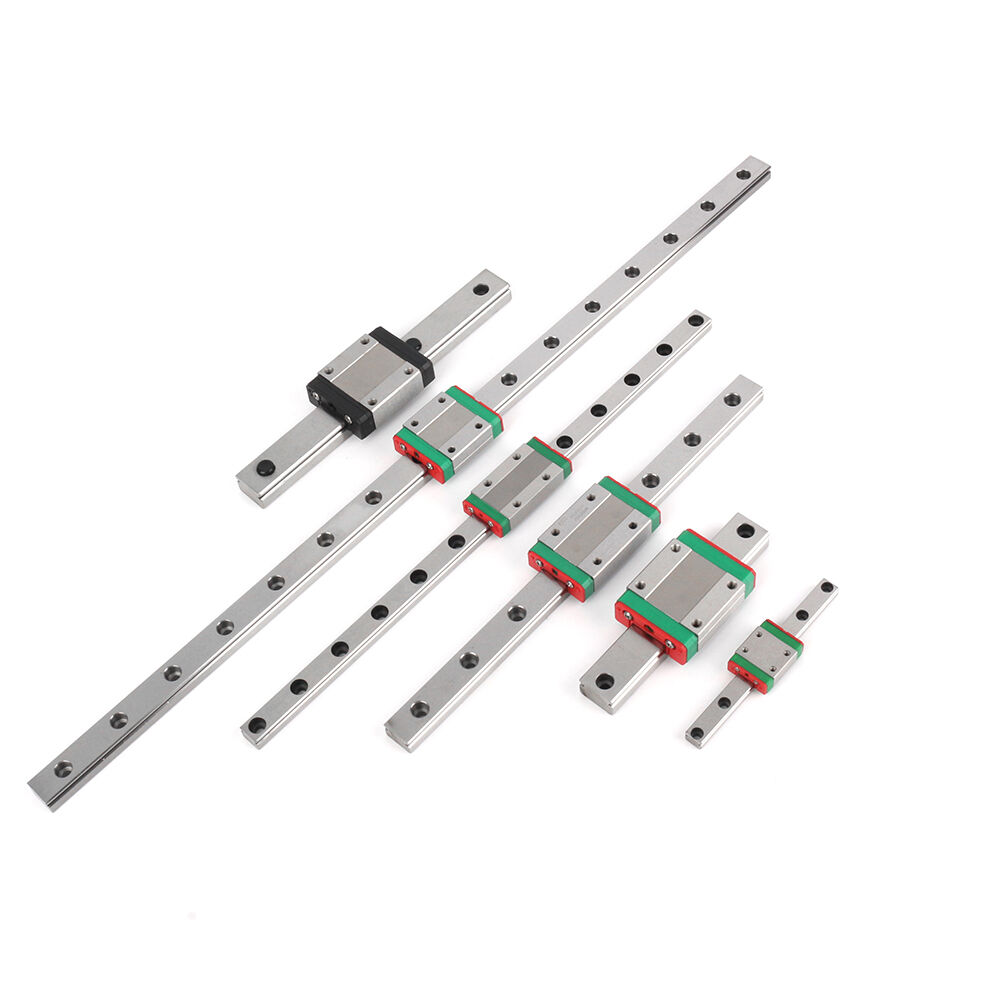

In the fields of precision automation, medical devices, semiconductor equipment, and 3C electronics manufacturing, Miniature Linear Guides serve as the core "motion joints" of machinery. However, as equipment designs become increasingly compact and application environments more complex, standard "off-the-shelf" products often fail to meet stringent engineering requirements.

To bridge the gap between standard products and specific needs, Customization Services have emerged. From specialized mounting holes to surface coatings designed for extreme environments, customized guides are becoming key to enhancing equipment competitiveness.

This article provides an in-depth look at the core customization processes available for miniature linear guides.

In mechanical design where space is strictly limited, every millimeter counts. Standard rail lengths or hole pitches can often become obstacles in structural design.

Standard rails are usually produced in fixed increments (e.g., every 60mm). This can lead to rails being too long (causing interference) or too short (insufficient stroke).

Precision Cutting: Rails can be cut to any length according to customer drawings, with tolerances controlled within $\pm 0.5mm$ or even tighter.

End Distance Control (E-Value): We can customize the distance from the rail end to the first mounting hole. This ensures that when multiple rails are butt-jointed, the hole pitch remains consistent across the joint, allowing for infinite extension.

While standard rails feature equidistant mounting holes, specific base plates may require custom layouts to accommodate clearance areas, sensors, or motor mounts.

Non-Standard Pitch: Re-arranging mounting holes to align perfectly with existing threads on your base plate.

Special Hole Types: Beyond standard countersunk holes, we offer:

Tapped Holes: For bottom-up mounting.

Dowel Pin Holes: For high-precision positioning/alignment.

Side Mounting Holes: For lateral attachment.

Miniature linear guides are typically made of stainless steel or bearing steel. However, in high-humidity, acidic/alkaline, or optical environments, the raw material alone is often insufficient. Chemical plating or physical treatments can endow the guides with specialized properties.

Process Characteristics: Hard chrome plating typically presents a bright, silver-white finish.

Core Advantages: Extremely high hardness and wear resistance, coupled with excellent rust prevention.

Application Scenarios: Ideal for automation lines with frequent reciprocating motion and high requirements for wear durability.

Process Characteristics: Electroless Nickel Plating (ENP) results in a uniform coating, typically slightly yellowish or bright silver.

Core Advantages: Superior corrosion resistance. Unlike chrome, nickel plating offers better coverage in complex geometries (such as inside the ball grooves), ensuring no "blind spots" for rust.

Application Scenarios: Medical devices, cleanroom equipment, or liquid handling systems in humid environments.

Process Characteristics: Using chemical oxidation or black chrome plating to form a dense black film on the surface.

Core Advantages:

Optical Extinction (Anti-Reflective): This is the primary function. The black surface absorbs light, preventing reflections from interfering with laser paths or visual sensors.

Rust Prevention: Provides basic oxidation protection.

Application Scenarios: Optical benches, laser cutting machines, microscope stages, and visual inspection equipment.

| Dimension | Standard Products | Customized Products |

| Design Freedom | Low; design must adapt to the rail parameters. | High; the rail adapts to the overall design. |

| Environmental Adaptability | Average; relies solely on raw material. | Strong; coatings resist acids, reflections, and wear. |

| Assembly Efficiency | May require secondary machining of the base plate. | Plug-and-play; perfect fit upon delivery. |

| Product Lifespan | Shorter in harsh environments. | Significantly extended due to targeted protection. |

Customization of miniature linear guides is not just about cutting metal or applying a coating; it is a deep optimization of mechanical performance and environmental chemical stability.

Whether you need to meet the strict "non-reflective" requirements of optical instruments, the high corrosion standards of medical equipment, or the unique mounting layouts of non-standard automation, professional customization services ensure your equipment stands out in both performance and stability.