I. Core Positioning and Nomenclature

Positioning: Ball screw support side (floating end) standard support bearing housing assembly. It is used at the end of the screw where axial thermal stress needs to be relieved.

Nomenclature Interpretation:

- B: Represents "Bearing Housing."

- F: Represents "Free" or "Float." This is its functional core—allowing the screw shaft to freely expand and contract minutely in the axial direction.

Core Functions:

- Primarily withstands radial loads: Supports the weight of the screw shaft, resists potential radial forces, and ensures concentricity of the screw's rotation.

- Allows axial free float: Internal bearing design enables the screw shaft to slide axially, absorbing thermal expansion caused by temperature rise, preventing screw bending, jamming, or loss of accuracy due to thermal stress.

- Provides radial positioning: Maintains the rotational center position of the screw shaft.

II. Core Structure and Components

A standard BF support unit is a highly integrated module, typically comprising:

Bearing Housing: Similar to the BK unit, with a precision-machined mounting flange and pilot.

Radial Bearing:

- Most common: Deep groove ball bearing. It effectively withstands radial loads while providing a degree of axial freedom (clearance).

- Other forms: Some models may use plain bushings (bronze sleeves) or needle roller bearings with cages, but deep groove ball bearings are most prevalent due to their low friction and high-speed capability.

Sealing System:

Features inner and outer seals to effectively prevent ingress of external contaminants and leakage of internal grease.

Grease Nipple: For periodic lubrication replenishment.

Axial Limiting Structure (Key Design):

- Unlike the BK unit, which "locks" the screw shaft, the fit between the BF bearing's inner ring and the screw shaft is typically a clearance or light push fit.

- The bearing outer ring is housed in the shell, with one end axially located and the other end left with axial clearance. This allows the entire bearing a small amount of axial movement space within the shell, enabling the screw to float.

III. Core Features and Advantages

- Key to Relieving Thermal Stress: This is the primary reason for the BF unit's existence. Ball screws generate frictional heat during high-speed or continuous operation, causing the screw shaft to expand thermally. If both ends were fixed (dual BK), the screw would buckle like a "propped-up" steel rail, leading to accuracy loss, abnormal wear, or even jamming. The BF end ingeniously resolves this issue by allowing axial float.

- Ensures System Operational Safety and Accuracy: By eliminating thermal stress, the BF unit ensures the screw remains straight across the entire operating temperature range, thereby maintaining transmission accuracy long-term and preventing catastrophic failure.

- Standardization and Ease of Use: Like the BK, the BF provides a ready-to-install, standardized solution, eliminating the need for users to design their own floating mechanism, ensuring performance and reliability.

- Good Radial Support: Despite allowing axial float, its radial support rigidity and precision remain high, effectively suppressing radial vibration (whipping) of the screw.

- Easy Maintenance: Integrated sealing and lubrication design extends maintenance intervals and simplifies procedures.

IV. System Coordination with BK Fixed End (Reiterating the Golden Rule)

This is a mandatory pairing relationship:

Drive Side / Reference Side: BK (Fixed End).

- Function: Withstands all bidirectional axial forces, provides the axial positioning reference.

- Screw Connection: Typically directly connected to the servo/stepper motor via a coupling.

Non-Drive Side / Slave Side: BF (Floating End).

- Function: Provides radial support, allows axial thermal expansion float.

- Screw Connection: This end of the screw is free or only connects to lightweight feedback devices like encoders.

Design Iron Law: A continuously rotating ball screw must, and can only, adopt the support method of [one end fixed (BK), one end floating (BF)]. This is a fundamental principle in all precision mechanical design.

V. Typical Application Fields

The application scenarios for BF support units are identical to those for BK units, as wherever a BK is used, a BF is necessarily used. It exists in all equipment employing precision ball screws:

- All types of CNC machine tools.

- Industrial robots and linear modules.

- Semiconductor manufacturing and inspection equipment.

- Precision automated production lines.

- Medical devices and scientific instruments.

VI. Selection and Usage Guidelines

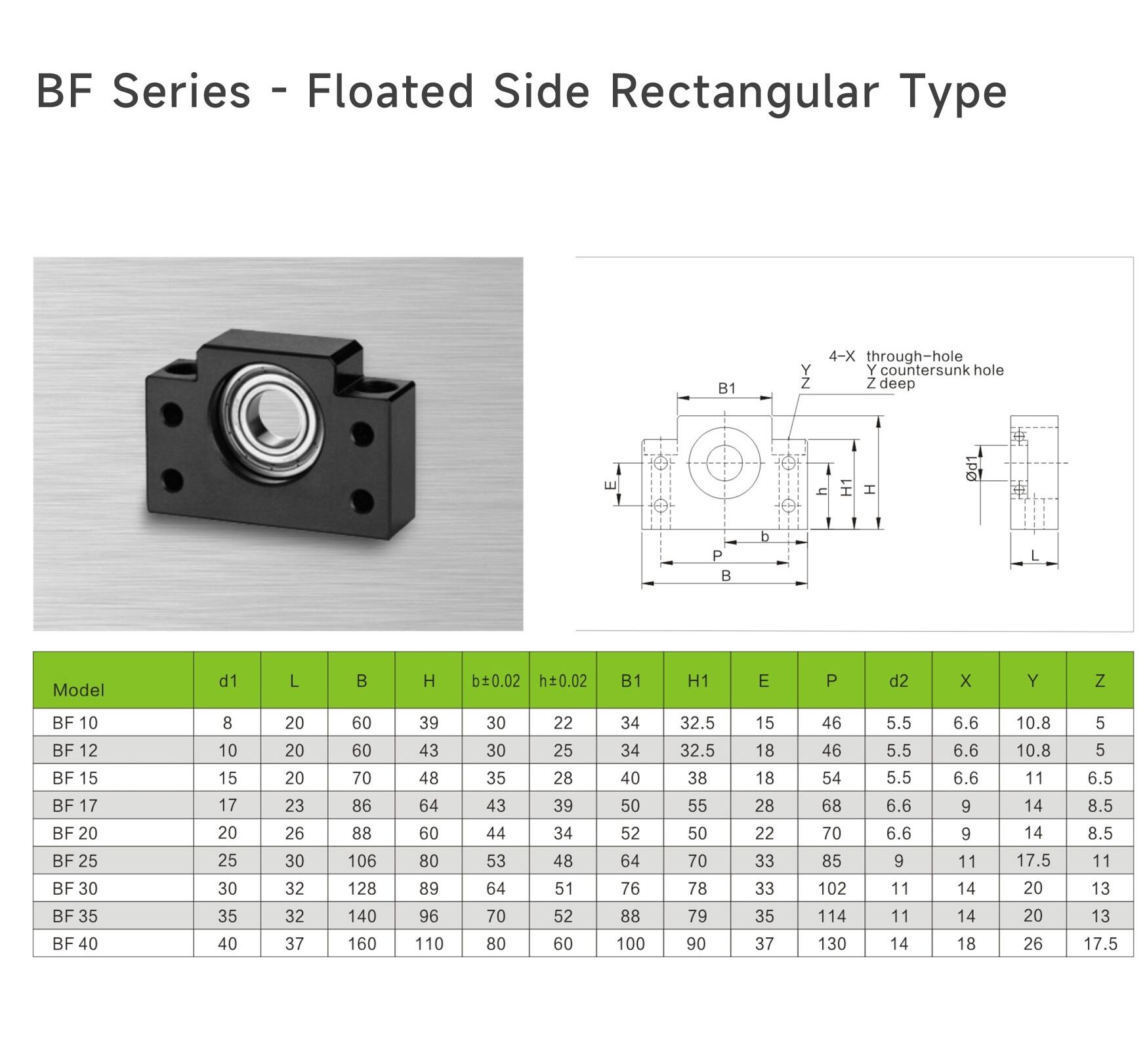

- Paired Selection: The BF unit must be selected as a pair with a BK unit of the same series and same shaft diameter specification (e.g., BK12 paired with BF12).

- Installation Position: Must be installed at the screw end furthest from the motor. If the screw is center-driven (less common), both ends should be BF floating ends, but such cases require special design.

- Avoid Axial Constraints: During installation, ensure there are no additional axial constraints on the screw shaft at the BF unit's end. For example, if an encoder is connected at this end, a flexible coupling must be used for the connection, and its bracket must not restrict the screw shaft's axial float.

- Correct Installation: Similar to installing BK, ensure the flatness of the BF mounting surface and its parallelism with the BK mounting surface to guarantee proper screw axis alignment.

- Maintenance: Periodically replenish grease via the grease nipple and check the seal condition.

If the BK fixed end is the system's "anchor" and "cornerstone," then the BF floating end is the system's "shock absorber" and "safety valve." In a clever and passive manner, it addresses the core challenge of thermal management in precision machinery. The design of the BF unit embodies the engineering wisdom of "overcoming hardness with softness"—using limited, controlled degrees of freedom to ensure the overall system's greater rigidity, accuracy, and reliability. Selecting and correctly using the BF support is another critical safeguard for ensuring the long-term, stable, and precise operation of a ball screw transmission system.