A smooth axis refers to a metal straight axis whose surface has undergone precise processing (usually grinding), has a cylindrical shape, and features high dimensional accuracy, high straightness and low surface roughness. It is a basic component in itself and needs to be used in conjunction with linear bearings (such as linear ball bearings and linear needle roller bearings) or sliding bushings to form a linear motion system.

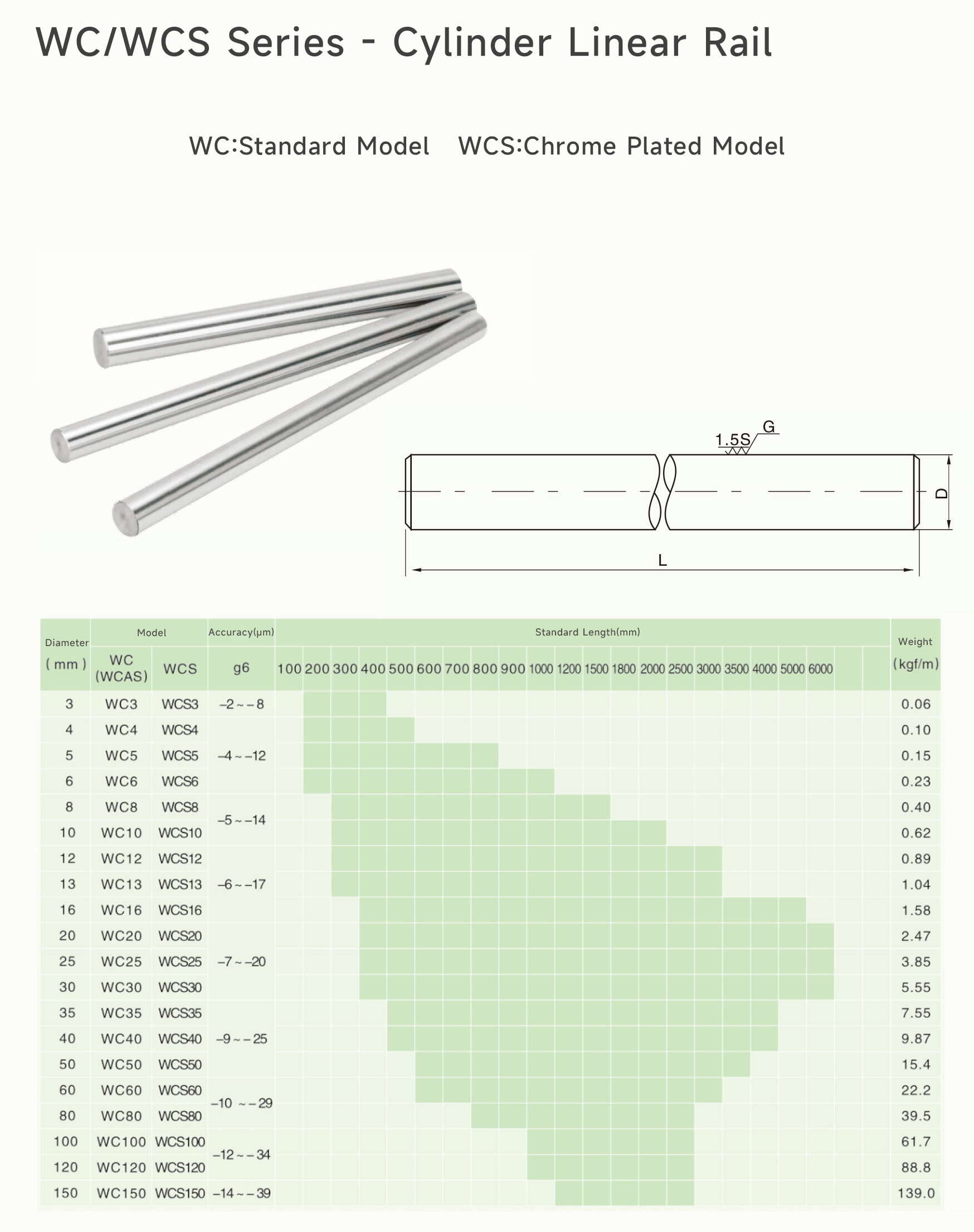

Positioning: High-precision, standardized cylindrical linear motion guide rail components. It is a core component of sliding friction or simple rolling friction linear guidance systems.

Key feature: "smooth " is mainly reflected in:

Classified by material and heat treatment:

Classified by precision grade:

Classified by structure:

Extremely high cost-effectiveness

Compared with ball/roller linear guides, the combination of a smooth shaft and linear bearings is the lowest-cost linear guidance solution, which is highly suitable for applications that are cost-sensitive and where the load and precision requirements are not extreme.

The optical shaft itself has a simple structure and can be easily fixed to the frame through the shaft support (flange type or square type). The layout is flexible and can achieve single-axis, double-axis or even multi-axis support structures.

The system is open and easy to assemble and maintain.

When used in conjunction with linear bearings, smooth linear motion can be achieved. Although the frictional resistance is higher than that of ball guides, it is much lower than that of ordinary sliding friction.

It can withstand a certain radial load.

The hard chromium layer is not only aesthetically pleasing but also rust-proof, making it suitable for equipment with high requirements for appearance.

There are standard diameter series (such as φ6, φ8, φ10, φ12, φ16, φ20, φ25...) The length can be customized and the market supply is abundant.

Characteristic |

Linear Shaft + Bushing System |

Ball/Roller Linear Guide (e.g., MGN/HGH) |

Guiding Principle |

The shaft rotates or remains stationary, while the bushing slides/rolls along it. Typically an open structure. |

The carriage block rolls along a precision rail. It is a closed or semi-closed structure. |

Friction Type |

Sliding friction or low-precision point contact rolling friction. |

High-precision rolling friction (balls or rollers). |

Rigidity |

Low. Acts as a cantilever support, offering very weak resistance to overturning and lateral moments. |

Very high. Designed with four-point contact, providing extremely strong resistance to overturning and lateral moments. |

Accuracy |

Relatively low. Subject to cumulative errors from shaft straightness, bushing clearance, and installation. |

Very high. Guaranteed high precision grade (parallelism, straightness) from the factory, offering stable accuracy after installation. |

Load Capacity |

Acceptable for radial loads, but almost incapable of bearing overturning moments. |

High load capacity in all four directions, specifically designed to withstand overturning moments. |

Operating Speed |

Low to medium. Prone to vibration and heat generation at high speeds. |

Suitable for high-speed and high-acceleration motion. |

Installation Requirements |

Deceptively simple; achieving high precision (e.g., dual-shaft parallelism) is very difficult, demanding high standards for mounting surface machining and adjustment. |

Features precision mounting reference surfaces; precision is ensured simply by screw tightening, offering good installation repeatability. |

Sealing & Lifespan |

Open structure, prone to contamination, requires frequent cleaning and lubrication, resulting in a relatively shorter lifespan. |

Integrated multi-layer seals provide dust and water resistance, maintain lubrication well, and offer a long lifespan. |

Cost |

Very low (for the components themselves). |

High |

Core Disadvantage |

Poor rigidity, low accuracy, and low tolerance for moments. |

High cost |

Application Philosophy |

“Good enough for basic guiding.” Suitable for light-load, low-cost, non-precision applications without significant lateral forces. |

“Precise and reliable guiding and load-bearing.” Suitable for applications demanding high load, high precision, high speed, and high rigidity. |

The optical axis system, with its extreme cost advantage, is still widely used in the following fields:

The optical axis is the most fundamental, economical, but also most performance-constrained component in the world of linear motion. Its essence is a "precise stick", and its core advantages lie only in low cost and simple structure. In modern precision mechanical design, it is increasingly being replaced by rolling linear guides that have a comprehensive performance advantage. However, in those situations where the load is extremely light, the precision requirements are low, the space is open, and the cost pressure is huge, the optical axis system remains a feasible option that cannot be ignored. Choosing the optical axis means that designers must make a clear and sometimes difficult trade-off between cost and performance.