The "SHF" is a specific model of linear shaft (straight shaft) support housing, belonging to the category of standardized mechanical components. Its core value lies in solving the critical problem of "how to conveniently, securely, and precisely install linear shafts and linear bearings."

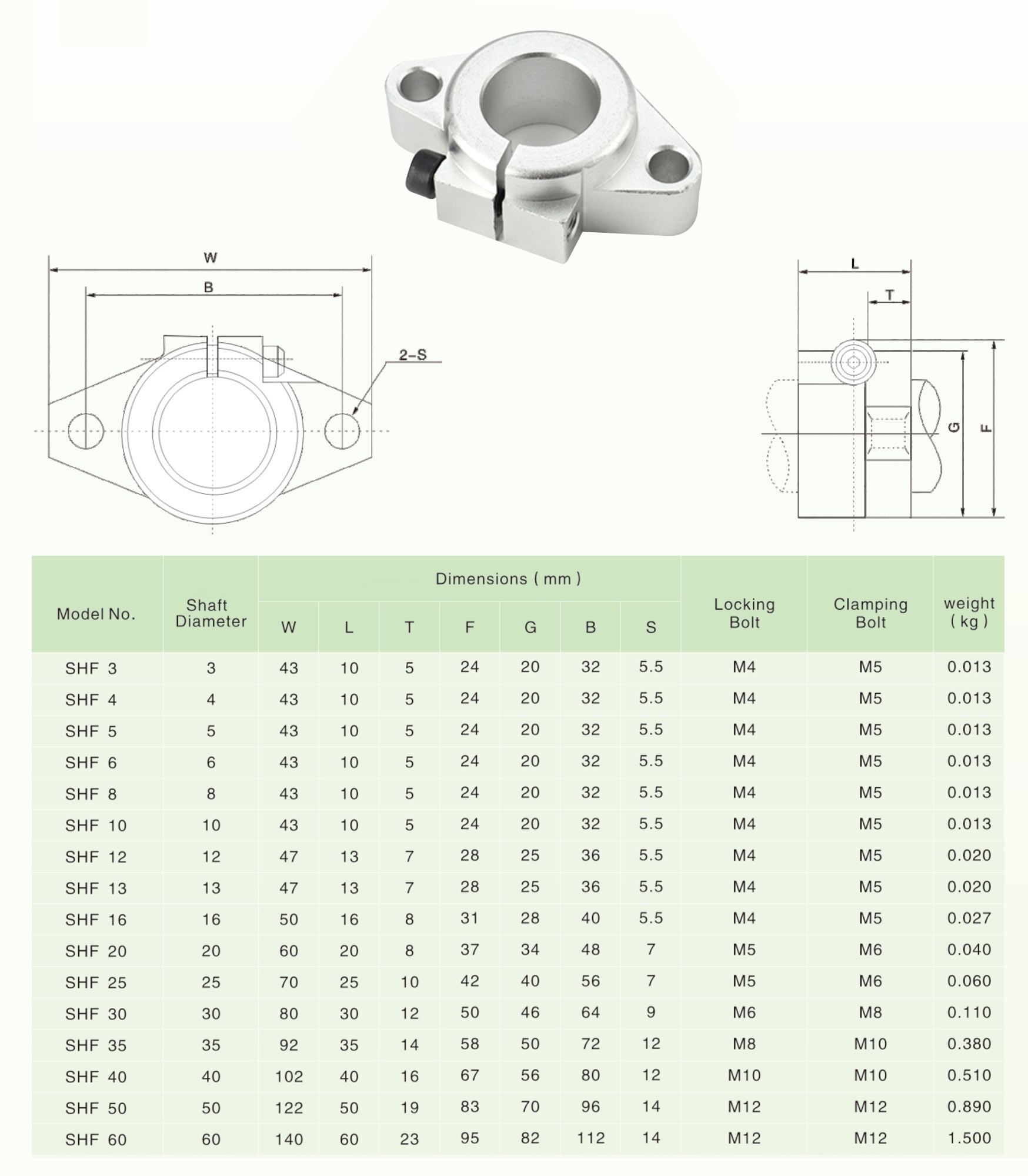

Positioning: A split-type (two-piece) flanged linear bearing housing. Used for fixing and supporting linear shafts and their matching linear bearings.

Nomenclature Interpretation:

S: Likely stands for "Support" or "Slide," indicating its use in linear motion support.

H: Typically represents "Housing."

F: Flanged, referring to its structure with a mounting flange containing screw holes, facilitating easy fixation to equipment panels or frames with screws. Most Critical Feature: "Split-type / Two-piece." The entire bearing housing is divided into an upper cap and a lower base along the axial plane.

Split-Type (Two-Piece) Structure: This is the greatest advantage of the SHF compared to solid bearing housings. It consists of an upper cap and a lower base connected by two locating pins and two (or four) socket head cap screws.

Advantage: No need for axial insertion from the shaft end. During assembly, after positioning the shaft and linear bearing, the two halves of the housing can be directly "clamped" around the bearing's outer ring and tightened. This greatly simplifies assembly and maintenance, especially in confined spaces or complex structures with multiple parallel shafts.

Flanged Mounting Surface: The base features a square or circular flange with multiple through-holes, allowing secure mounting to equipment panels, aluminum extrusions, or frames, providing excellent mounting rigidity.

Precision Bore and Positioning: The housing bore is precision-machined to achieve a precise transition or slight clearance fit with the outer diameter of standard linear bearings (e.g., LM, SC series), ensuring the bearing is fixed securely and concentrically. Snap ring grooves are typically provided at both ends of the bore for installing snap rings (retaining rings) to prevent axial movement of the linear bearing.

Standard Materials and Surface Treatment: The main body is commonly made of carbon steel (e.g., SS400) or aluminum alloy (e.g., A5052). Carbon steel offers high rigidity, while aluminum alloy provides lightweight and corrosion-resistant properties. Surfaces are often treated with black anodizing (aluminum alloy) or nickel plating (carbon steel) for corrosion resistance and aesthetic appeal.

Unparalleled Installation Convenience (Core Advantage):

Assembly Revolution:Completely eliminates the challenge of long-travel assembly required by traditional solid housings, where shafts and bearings must be slid on from one end. The advantage is particularly evident in confined spaces, pre-assembled frames, or during maintenance and replacement.

Ensured Concentricity and Installation Precision:The precision-machined bore and split design ensure the linear bearing is clamped evenly, preventing deformation due to installation stress, thereby guaranteeing smooth shaft movement.

High-Rigidity Fixation:The flanged design provides a stable mounting foundation, effectively resisting minor vibrations and radial forces generated during the motion of the shaft system.

Standardization and Interchangeability:Available in a comprehensive range of standardized sizes, perfectly matching standard shaft diameters (φ6, φ8, φ10...) and linear bearing models. This simplifies design selection and procurement.

Facilitates Maintenance and Adjustment:When bearing replacement or shaft position adjustment is needed, simply loosening the screws allows the cap to be removed, without requiring disassembly of the entire shaft or other components, significantly improving maintenance efficiency.

| Feature | SHF (Split Flange Housing) | Solid Flange Housing | Pillow Block (Open Bearing Housing) |

| Structure | Split into upper and lower halves. | Single solid piece with a through bore. | Base and cap are separable, typically used for rotating shaft bearings. |

| Installation | “Clamshell” assembly; no need to slide from shaft end. | Must be slid onto the shaft from the end. | “Clamshell” assembly, but structure is more focused on rotary support. |

| Suitability | Ideal for securing linear bearings & shafts; highly flexible assembly. | Suitable for simple structures with unobstructed shaft ends; lowest cost. | Primarily for mounted ball bearings supporting rotating shafts; can be used for shafts but not optimal. |

| Self-Alignment | None. Relies on mounting surface accuracy for alignment. | None. | Some models offer self-aligning capability, tolerating certain installation misalignment. |

| Typical Use | Linear motion systems (shaft + linear bearing). | Simple or initial assembly structures. | Rotary drive systems (pulley, sprocket shafts). |

The SHF support housing is the most standard and recommended fixing component in linear motion modules using the shaft-and-bearing combination. It is widely used in:

Automation Equipment and Framing: For constructing various XY stages, gantry systems, and lifting mechanisms.

3D Printers (Mid-to-High Range): Fixing shafts, providing precision guidance support for print heads or heated beds.

Precision Instruments and Laboratory Equipment: Sliding components on optical platforms, sample positioning mechanisms.

Packaging and Feeding Machinery: Guiding and supporting reciprocating rods.

Light-Duty CNC Machinery: Such as guide shaft fixation in engraving machines and small laser cutters.

Any linear motion application requiring convenient disassembly and maintenance.

Three-Step Sizing Process:

Step 1 (Determine Shaft): Based on load and rigidity requirements, determine the shaft diameter (e.g., φ12).

Step 2 (Determine Bearing): Select the standard linear bearing model matching the shaft diameter (e.g., LM12UU).

Step 3 (Determine Housing): Select the corresponding SHF support housing model based on the bearing's outer diameter (e.g., SHF12).

Installation Precision is Critical:

Parallelism: The mounting surfaces for multiple shafts or multiple support housings must be coplanar and strictly parallel. This is essential for ensuring smooth, non-binding movement. Fine adjustment using a dial indicator is often necessary.

Concentricity: The bore centers of a pair of support housings (supporting both ends of a single shaft) must be precisely aligned.

Correct Use of Snap Rings:Always install standard snap rings into the grooves at both ends of the housing bore to restrict the axial movement of the linear bearing, preventing it from gradually sliding out during use.

Screw Tightening Torque:Tighten the screws connecting the cap and base to the recommended torque to ensure the bearing is securely clamped. Avoid excessive force to prevent thread stripping in aluminum housings or deformation of the housing.

The SHF linear shaft support housing is an outstanding representative of modern modular, easy-to-maintain design. It transforms a simple installation challenge into an efficient, reliable, and user-friendly standardized solution through its ingenious "split" structure. Choosing SHF means prioritizing assembly and maintenance convenience, system adjustability, and long-term reliability when designing linear shaft systems. Although it is a small component, it is an indispensable "excellent connector" for building stable and flexible linear motion systems.