"EK" typically refers to another structural form of the ball screw fixed-end support unit, specifically denoting an "eccentric locking collar type" fixed-side support unit. It is functionally identical to BK (fixed end)—both withstand bidirectional axial forces and fix the axial position of the screw—but differs fundamentally in the method of locking the screw shaft.

Positioning: A ball screw fixed-side support unit that uses an eccentric locking collar for fixation. It is a fixed-end solution that does not require a shaft shoulder or locknut.

Nomenclature Interpretation:

Core Value: Provides a simple, reliable, and high-rigidity fixed-end support solution for screw shafts without machined shoulders, particularly suitable for space-constrained applications or situations where simplifying shaft end machining is desired.

The EK unit is identical to the BK unit in the bearing section (typically using paired angular contact ball bearings). The key difference lies in the locking mechanism between the bearing inner ring and the screw shaft:

Eccentric Locking Collar:

This is the core component of the EK unit. It is a precision sleeve with a longitudinal slit. Its inner bore has a precise clearance fit with the screw shaft, and its outer diameter fits the bearing inner bore. The sleeve's outer surface features an eccentric lug or wedge profile.

Locking Ring/Locknut:

A locking ring with an inner conical bore or inner eccentric bore is threaded onto the bearing housing.

Locking Principle (Two-Step Process):

Key Point: EK achieves axial fixation through the high friction generated by radial clamping, eliminating the need for a machined shoulder on the screw shaft, as well as threading the shaft end and installing a locknut.

| Feature | EK (Eccentric Locking Fixed End) | BK (Shoulder & Locknut Fixed End) |

| Screw Shaft End Requirement | Plain shaft is sufficient. No shoulder or threading required. | Must have machined shoulder and threading for bearing contact and locknut tightening. |

| Locking Principle | Radial friction locking (eccentric sleeve clamping the shaft). | Axial mechanical preload (shoulder contacts bearing + locknut tightening). |

| Axial Space | More compact, saves space by eliminating shoulder and locknut. | Requires reserved space for shoulder and locknut. |

| Installation Convenience | Very high. Insert shaft and tighten one ring. Position is adjustable. | Requires ensuring shoulder length and using two wrenches to tighten locknut and lock washer, involving more steps. |

| Applicability | High versatility, especially suitable for space-constrained designs, standard plain shafts, simplified machining, or scenarios requiring axial position adjustment. | Traditional, classic, most widely used method. Suitable for all applications with sufficient space and screw shafts machined to standard. |

| Cost | Support unit itself may be slightly more expensive, but screw shaft machining cost is lower. | Support unit may be slightly less expensive, but screw shaft requires additional machining. |

The EK support unit, due to its flexibility, is suitable for various applications, particularly offering clear advantages in specific scenarios:

Confirm Shaft End Form: Clearly determine if the screw shaft is a plain shaft without shoulders. If yes, EK is ideal. If it already has shoulders, BK is more suitable.

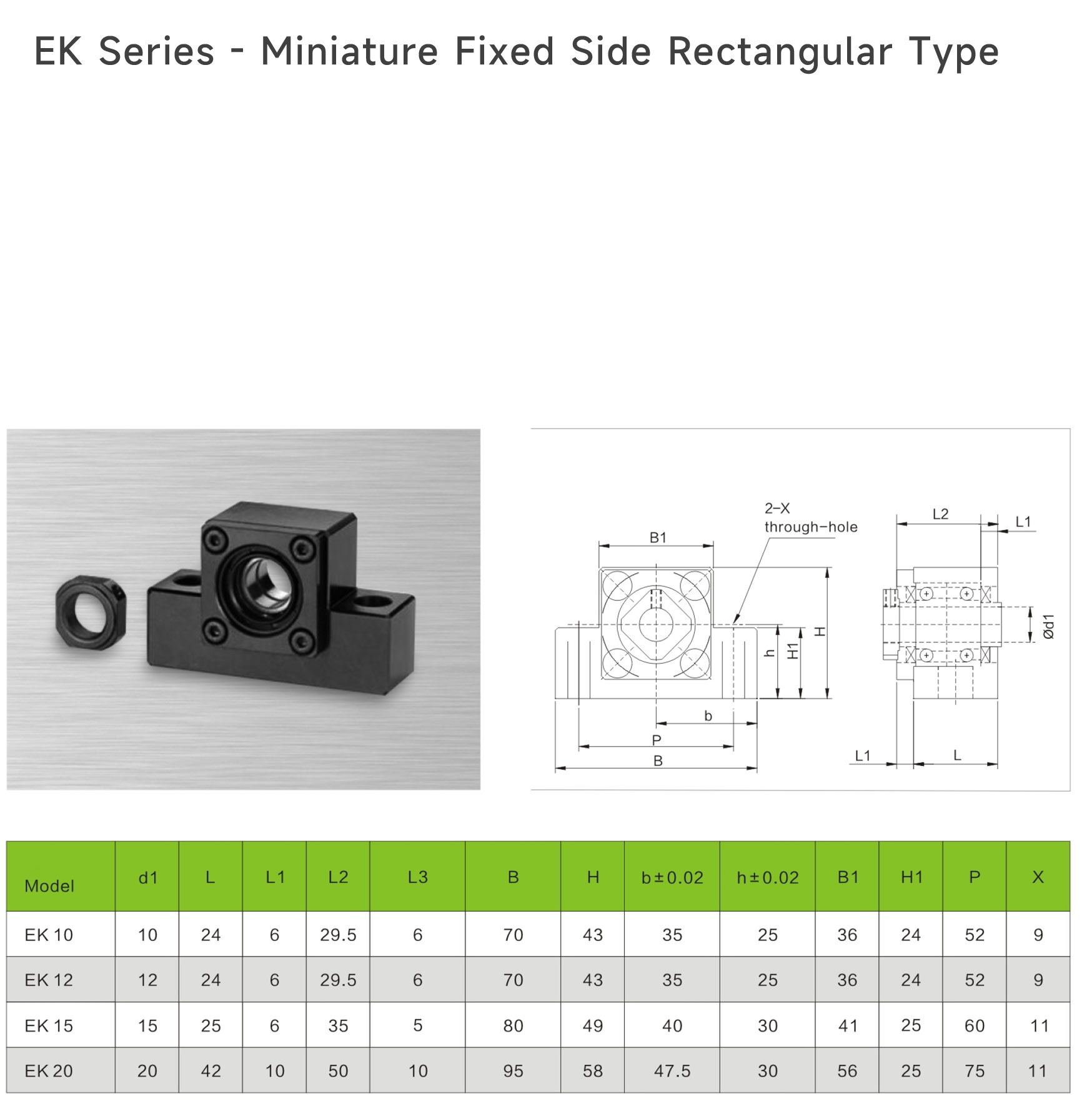

Match Shaft Diameter: Strictly select the corresponding EK unit model based on the screw shaft diameter.

Correct Installation:

Paired Usage: Like BK, EK must be paired with a BF or FK floating end to release thermal stress.

Finalize Axial Position Before Locking: Perform the final locking operation only after definitively determining the axial position of the screw shaft relative to the nut and worktable.

The EK support unit is an important "user-friendly" innovation in fixed-end support technology. Through its ingenious eccentric locking collar design, it shifts the challenge of fixation from "shaft machining" to "support unit design," providing greater convenience and flexibility for equipment designers and assembly engineers. Choosing EK means obtaining a more compact layout, easier installation, and lower screw shaft machining requirements while ensuring performance equivalent to traditional BK. It is a highly valuable option in modern precision equipment design.