"LM" is the most universal and standard model prefix for "Linear Motion Bearings," having almost become synonymous with this type of bearing. The LM series represents the benchmark and performance standard in the field of linear bearings, embodying the most mature and classic design.

Positioning: Standard, high-performance linear ball bearings. It is the most widely used and performance-balanced linear bearing, serving as the reference for evaluating other types (e.g., SCS, SC).

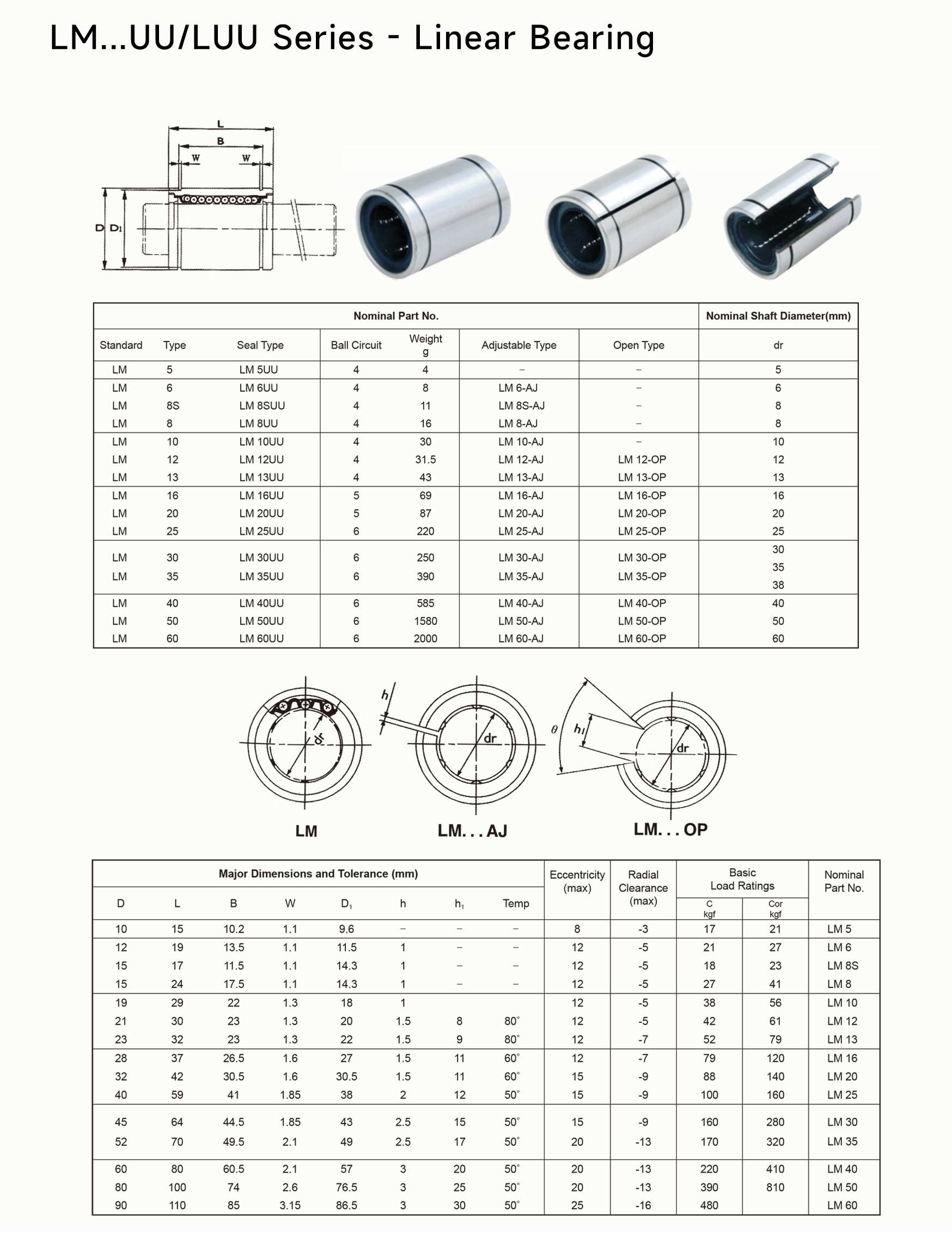

Nomenclature Interpretation:

High-Performance Bearing Steel Housing:

The housing is made of high-quality bearing steel (e.g., GCr15/SUJ2), subjected to through-hardening and precision grinding, achieving extremely high hardness (HRC 58-62). It offers the best wear resistance, impact resistance, and rigidity among all types.

Precision Ball Cage:

The cage is typically made of high-rigidity engineering plastic (e.g., POM) or steel, designed to precisely separate and guide the balls.

Multiple Ball Rows: Usually features 3 or 6 symmetrically arranged ball rows, ensuring radial load capacity and allowing slight self-alignment.

Double-Sided Contact Seals (UU-Type Mark):

Both ends of the bearing are equipped with rubber or polyurethane seals, effectively preventing ingress of dust and chips while retaining internal grease, significantly extending service life and maintenance intervals. This is a key design that established it as an industrial standard.

Lubrication Structure:

Standard Snap Ring Groove:

The outer ring features a standard groove for installing a retaining ring (circlip) to secure it axially within a support block.

Highest Comprehensive Performance:

Outstanding Durability and Long Service Life:

All critical components (housing, balls) are made of high-hardness steel, offering excellent wear resistance. Combined with effective seals, it maintains a long life even in harsh environments.

Excellent Sealing and Dust Protection:

The "UU" type seal ensures industrial-grade protection, enabling use in workshop environments with light dust or moisture, not just clean rooms.

Smooth Operation, Low Noise:

Precision manufacturing processes and preload design (in some models) ensure smooth, quiet operation.

Extremely High Reliability:

Decades of industrial validation have refined its design and manufacturing process to near perfection, resulting in a very low failure rate. It is the most "dependable" choice in the minds of engineers.

| Feature | LM/UU (Standard High-Performance) | SCS (Steel Bushing Economical) | SC (Aluminum Housing Lightweight) |

| Housing Material/Process | Bearing steel, through-hardened + precision ground, highest hardness. | Carbon steel, surface treated (plated/coated), hardness depends on base material. | Aluminum alloy, lightweight but soft. |

| Core Positioning | Performance benchmark. High load, high rigidity, long life. | Balanced cost-performance. Balance between durability and cost. | Extreme lightweight. |

| Load Capacity | Highest. | Medium. | Lowest. |

| Rigidity | Highest. | High. | Low. |

| Wear Resistance | Excellent. | Good. | Poor. |

| Sealing | Standard double-sided seals (UU). | Typically unsealed or simple seals. | Typically unsealed. |

| Price | Highest. | Medium. | Lowest (or comparable to SCS). |

| Selection Logic | Pursuing best performance, reliability, and lifespan; budget is sufficient. | General industrial applications requiring decent performance but with strict cost control. | Scenarios where weight is a critical constraint (e.g., high-speed robot arms). |

LM bearings are the preferred choice for industrial equipment with high demands, heavy loads, and continuous operation:

Model Interpretation and Selection:

Must Be Paired with High-Precision Shafts:

The full performance of LM bearings depends on ultra-high precision hard chrome or ground shafts. Shaft quality directly determines system life and accuracy. Never pair with ordinary soft shafts.

Correct Installation into Support Blocks:

Must be installed into standard support blocks like SHF or SK. Always install retaining rings to prevent axial movement of the bearing. Avoid direct hammering during installation; use a dedicated sleeve for pressing.

Lubrication and Maintenance:

Even though pre-greased, after prolonged or high-speed use, replenish with the specified high-speed grease via the shaft or the bearing's own grease nipple (e.g., OP type).

Load Direction:

Primarily designed to withstand radial loads. Although symmetrical in structure, design should aim to have the load pass through its center as much as possible, avoiding excessive off-center loads or moments.

The LM linear bearing series is a "classic masterpiece" and the "performance king" in linear motion technology. It represents the pinnacle of linear ball bearing design—achieving excellence in materials, craftsmanship, sealing, and reliability. Although its unit cost is the highest, considering the ultra-long life, extremely low failure rate, and maintenance costs it delivers, its total lifecycle cost in serious industrial applications is often the lowest. Choosing LM means selecting a "top-tier guarantee" and "zero-compromise" solution for a machine's core motion mechanism. It is the definitive choice for pursuing exceptional performance and enduring reliability.