I. Core Positioning and Nomenclature

Positioning: Ball screw fixed side (fixed end) standard support bearing housing assembly. It is used at the end of the screw where complete axial and radial positioning is required.

Nomenclature Interpretation:

- B: Typically represents "Bearing Housing."

- K: Represents "Fixed" or "Klamp" (originating from German or industry convention), signifying its core function—securely locking the screw shaft at this end.

Core Functions:

- Withstands bidirectional axial loads: Bears the axial forces generated during screw transmission in both forward and reverse directions.

- Withstands radial loads: Supports the weight of the screw and potential radial forces.

- Provides precise axial positioning reference: The screw shaft is rigidly fixed at this end, serving as the axial coordinate origin for the entire motion system.

- Allows free screw rotation: Internal bearings enable high-speed, low-friction rotation of the screw.

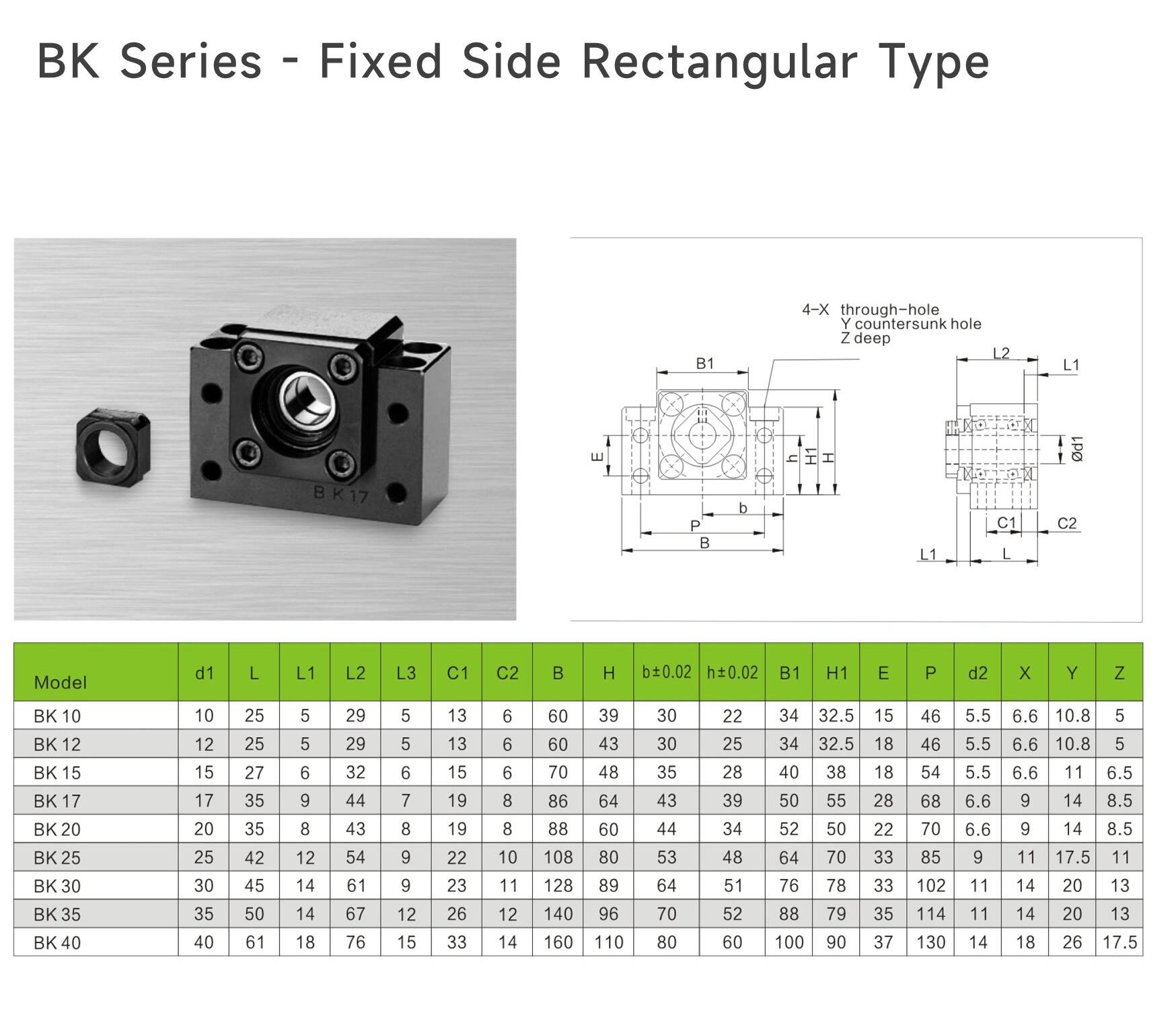

II. Core Structure and Components

A standard BK support unit is typically an integrated, ready-to-install module comprising the following components:

- Bearing Housing: Usually made of cast iron or steel, featuring a mounting flange and pilot to ensure installation accuracy.

- Angular Contact Ball Bearings (Paired): The heart of the BK unit. Typically installed in pairs in a "back-to-back (DB)" or "face-to-face (DF)" configuration to provide high bidirectional axial rigidity and load capacity. The bearings are of high precision grade (typically P4 or P5).

- Locknut and Lock Washer: Used to press the screw shaft shoulder against the bearing inner ring and lock it in place, achieving axial fixation of the screw shaft.

- Sealing System:

- Inner seal: Prevents bearing grease from leaking toward the screw nut side.

- Outer seal: Often a contact lip seal or labyrinth seal to prevent ingress of external contaminants such as dust, chips, or coolant.

- Grease Nipple: For periodic replenishment of high-performance grease.

- Preload Adjustment Mechanism (Some High-End Models): Allows optimization of bearing rigidity and temperature rise through shims or threaded adjustment of the preload force.

III. Core Features and Advantages

-

High Rigidity and High Load Capacity:

The paired angular contact ball bearing configuration provides optimal axial rigidity, effectively resisting elastic deformation under load, which is crucial for ensuring system positioning accuracy.

-

Standardization and Modularity:

Available in various sizes matching screw shaft diameters. Users can immediately install and use the unit without the need to independently select, install, or adjust complex angular contact bearing pairs. This greatly simplifies the design, procurement, and assembly processes while ensuring consistent performance.

-

Excellent Sealing:

The integrated multi-seal design offers more reliable sealing than user-assembled bearings, making it particularly suitable for harsh environments such as machine tools and automation equipment where dust, moisture, or coolant are present.

-

Easy Installation and Good Alignment:

The housing is precision-machined, with the pilot ensuring perpendicularity between the bearing bore and the mounting surface, simplifying alignment adjustments.

-

Long Service Life and Easy Maintenance:

Pre-filled with long-life grease and easily replenished via the grease nipple, it offers extended maintenance intervals and simple operation.

IV. Coordination with the Opposite End Support Unit (BF/FK)

A complete ball screw drive system must employ different types of supports at each end to accommodate thermal expansion:

Fixed End (BK Side): Completely fixes the axial and radial position of the screw. Typically installed on the drive motor side.

Support/Floating End (BF/FK Side):

- BF: "B" stands for bearing housing, "F" stands for "Free" or "Float." It typically uses deep groove ball bearings or plain bushings to mainly withstand radial loads while allowing slight axial thermal expansion float of the screw shaft, preventing bending due to thermal stress from temperature rise.

- FK: Similar in function to BF, it is another common floating end support model.

Golden Rule: A single screw must have exactly one BK fixed end, and the other end must be a BF or FK floating end.

V. Typical Application Fields

BK support units are standard components in all equipment using precision ball screws, with ubiquitous applications:

- CNC machine tools: Drive end of ball screws in feed axes of machining centers, lathes, milling machines, grinders, etc.

- Industrial robots: Screw ends in joint drives and linear motion modules (slides).

- Precision automation equipment: Semiconductor equipment, chip mounters, measuring machines, laser processing equipment.

- Printing and packaging machinery.

- Medical devices.

VI. Selection and Usage Guidelines

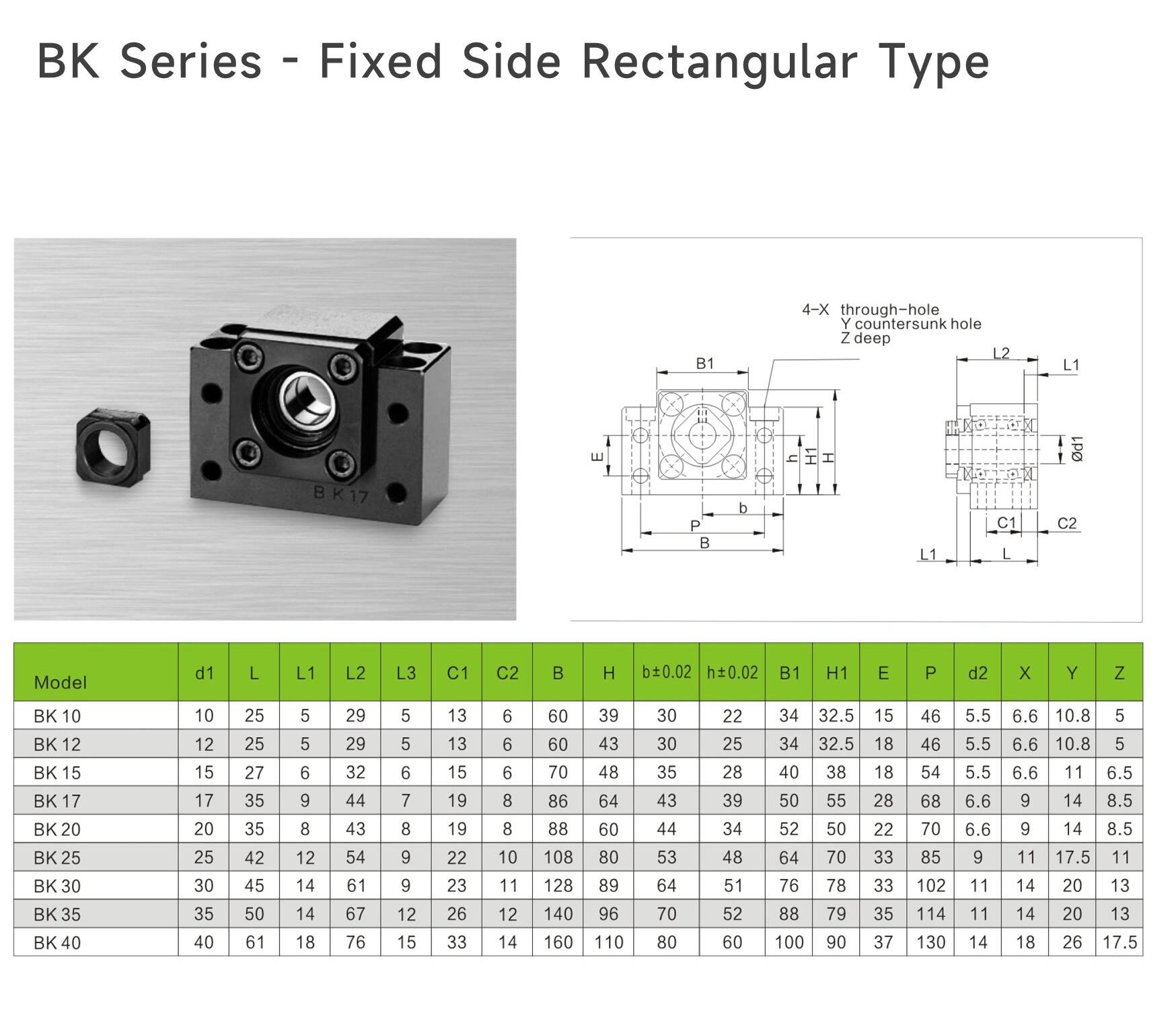

Size Matching: The nominal model of the BK unit (e.g., BK10, BK12, BK15) must strictly match the diameter of the screw shaft end used.

Load and Accuracy Verification: Select standard or reinforced BK units based on the maximum axial load the screw will bear and the required system rigidity. High-precision equipment requires models with high-precision bearings.

Correct Installation Orientation:

- Ensure the screw shaft shoulder is pressed firmly against the inner ring of the bearing inside the BK unit.

- Use a dedicated wrench to tighten the locknut to the recommended torque and properly utilize the lock washer.

Paired Usage: Always purchase a corresponding BF or FK floating support unit for the opposite end of the screw.

Lubrication: Before initial use, verify that the unit is pre-greased, and periodically replenish with the specified grease via the grease nipple according to the equipment maintenance manual.

The BK support unit is an indispensable "anchor" in precision ball screw transmission systems. It encapsulates complex issues such as bearing selection, pairing, preloading, and sealing into a reliable, easy-to-use standardized functional module. Selecting the correct BK unit and properly pairing and installing it with a BF unit is the crucial first step in establishing a stable, precise, and durable foundation for the entire linear motion system. It is one of the "standard solutions" that engineers can confidently rely on in design.