I. Core Positioning and Nomenclature

Positioning: A ball screw system with double floating end supports. This is a non-standard but highly targeted support method.

Nomenclature Interpretation:

- First F: Indicates that one end of the screw is supported by a floating end.

- Second F: Indicates that the other end of the screw is also supported by a floating end.

Core Value: Designed to address the significant axial elongation due to thermal expansion in ultra-long stroke screws or for special layouts where the screw is driven from the middle section.

II. Core Structure and Working Principle

The FF configuration abandons the traditional one-end-fixed model. Its working principle is as follows:

Completely Releases Thermal Stress:

Both ends allow axial float, enabling the screw to expand freely in both directions when heated, rather than being forced to expand only toward one end as in a one-end-fixed system.

Result: The axial compressive stress within the screw caused by thermal expansion is minimized, fundamentally preventing the risk of buckling (bending) in long screws due to thermal stress.

Transfer of Axial Positioning Reference:

In traditional BK-FK systems, the BK end serves as the absolute axial position reference.

In FF systems, the ball nut itself (or the worktable rigidly connected to the nut) becomes the axial positioning reference for the system. The screw shaft can freely "float" within the supports at both ends, while the nut's position is controlled and locked by the drive system (e.g., a servo motor).

Typical Drive Methods:

- Mid-Section Drive: The motor drives the middle section of the screw via a timing belt or gears. This is the most common application scenario for FF support, where both ends of the screw are supported but do not transmit drive torque.

- End Drive (Less common, requires special design): Even if driven from one end, that end uses a floating support and requires a corresponding torque support device (e.g., splines or guide keys) to withstand the rotational drive torque while allowing axial movement.

III. Core Features and Advantages

-

Designed for Ultra-Long Strokes:

This is the primary advantage of FF support. When the screw length is very long (e.g., exceeding 3-4 meters), the cumulative elongation due to temperature rise is substantial. The double floating design is the most effective and reliable engineering solution for managing this significant thermal expansion.

-

Eliminates Buckling Risk, Enhances System Reliability:

Completely resolves the potential instability and bending issues of slender screws under thermal and compressive loads, greatly improving the operational safety and accuracy retention of long-stroke systems.

-

Layout Flexibility:

Allows for mid-section drive, enabling heavy drive motors to be placed in the middle of the stroke or on the equipment frame rather than at the stroke ends, optimizing the overall center of gravity and structural design of the equipment.

-

Reduces Stringent Requirements for Support Installation Accuracy:

Since neither end bears strict axial positioning functions, the requirements for the axial relative position accuracy of the two support unit mounting surfaces can be relaxed somewhat (though requirements for parallelism and coaxiality remain high).

IV. Typical Application Scenarios

FF support is a solution-oriented design primarily used in the following specific fields:

- Extra-large CNC machine tools: Such as X-axis (gantry beam) of gantry machining centers and floor-type boring/milling machines with strokes reaching tens of meters.

- Large laser cutters/waterjet cutters: Wide sheet material processing equipment.

- Large-scale measuring equipment: Such as bridge-type coordinate measuring machines (CMMs), rail-type measuring machines.

- Special heavy industrial equipment: Such as wind turbine blade grinding machines, ship section welding platforms.

- Special automation equipment with mid-section drive: Where structural layout constraints necessitate placing the drive motor in the middle of the stroke.

V. Comparison with Traditional One-End-Fixed (BK-FK) Systems

| Feature |

FF (Double Floating End) System |

Traditional BK-FK (One End Fixed) System |

| Support Configuration |

Both ends are floating ends (BF/FK/EF). |

One end fixed (BK/EK), one end floating (BF/FK/EF). |

| Thermal Expansion Handling |

Screw expands freely toward both ends, no internal compressive stress. |

Screw expands only toward the floating end, generating thermal stress at the fixed end. |

| Axial Reference |

Uses the ball nut/worktable as the reference. |

Uses the fixed-end support (BK) as the reference. |

| Suitable Stroke |

Essential solution for ultra-long strokes (typically 3-4 meters). |

Standard solution for short, medium, and long strokes (typically <3 meters). |

| Drive Method |

Often mid-section drive (belt/gear). |

Almost exclusively end drive (motor directly coupled or via coupling). |

| System Complexity |

Higher. Requires additional torque transmission and anti-rotation mechanisms. |

Standard, simple, mature technology. |

| Application Frequency |

Specialized application, addressing specific problems. |

General application, constitutes the vast majority. |

VI. Important Design Considerations and Precautions

- Anti-Rotation Mechanism: Since both ends of the screw are not fixed, it is essential to prevent unwanted rotation of the screw relative to the supports during driving. For mid-section or end drives, an anti-rotation device such as a spline pair, guide key, or rotation lock fixture is typically installed near one support end, allowing only axial movement while transmitting rotational torque to the frame.

- Rigidity of Nut as Reference: The overall axial rigidity of the system depends on the rigidity of the connection between the nut and the worktable, which needs to be specifically reinforced.

- Position Feedback: The motor encoder provides feedback on the motor shaft position, not the worktable position. For high-precision systems, a full-closed-loop feedback system (e.g., linear encoder/scale) that directly measures the worktable position is mandatory.

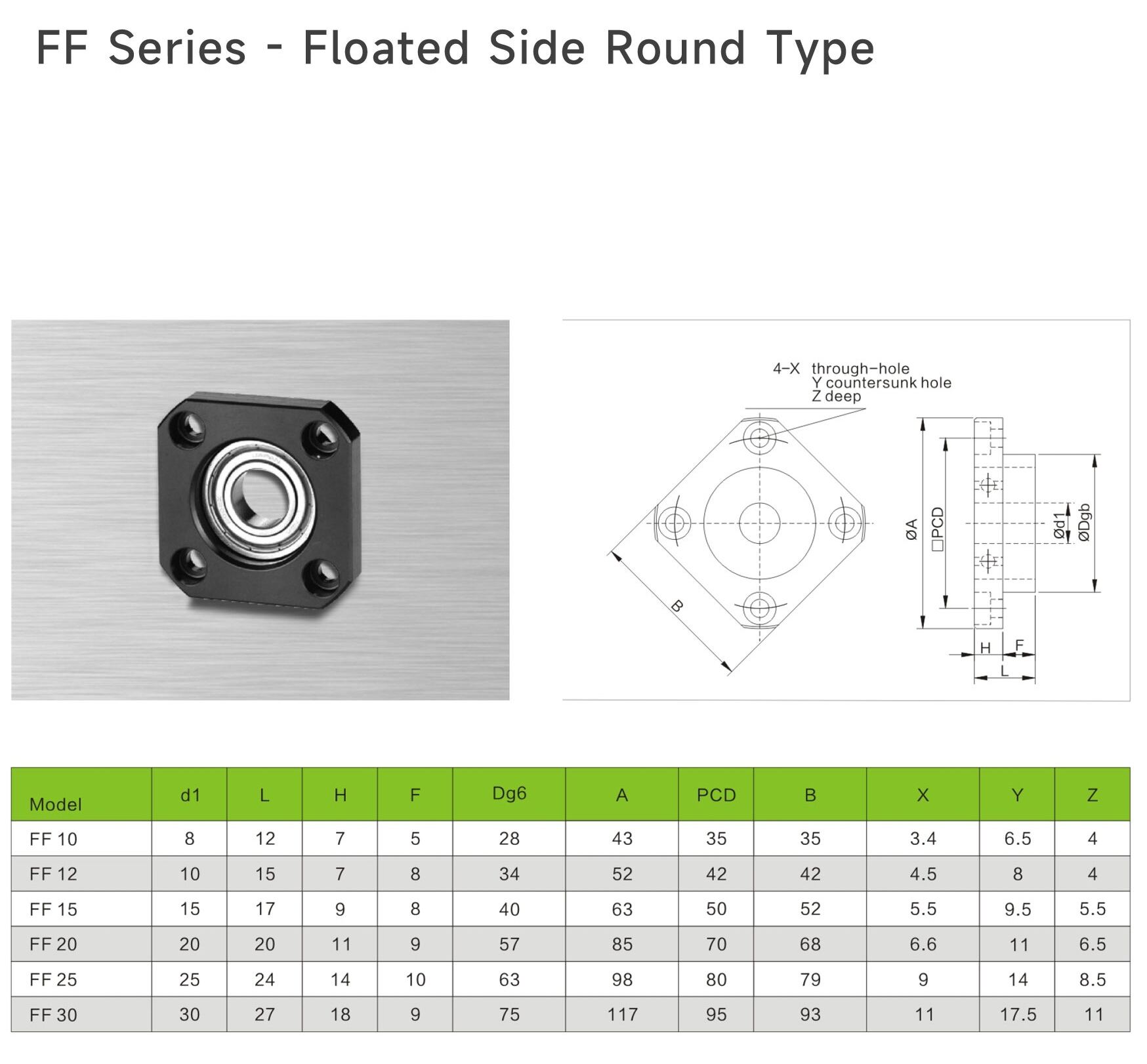

- Support Selection: The floating supports at both ends can be BF, FK, or EF, depending on space and screw shaft type, but both must have floating functionality.

- Not a Performance Enhancement Method: FF is specifically for solving the problem of "long-stroke thermal expansion." For equipment with standard strokes, the traditional one-end-fixed method offers advantages in rigidity, cost, and complexity.

The FF support configuration is a highly specialized engineering solution targeted at the challenge of "thermal management for ultra-long strokes." It achieves safety and stability at extreme scales by completely freeing the screw from "axial constraint." Choosing an FF system indicates that the equipment design has entered the specific domain of large-scale, heavy-duty applications, requiring engineers to have a deeper understanding and more meticulous design regarding thermodynamics, structural mechanics, and motion control. It is not a universal choice, but within its applicable field, it is an irreplaceable key technology.