"SCS" typically refers to a standard type linear ball bearing with a "steel sleeve." The letter "S" often stands for "Steel Sleeve," distinguishing it from another common series, "SC" (aluminum housing). It is a type of linear ball bearing and serves as the core moving component in a "shaft + linear bearing" sliding system.

Positioning: A standard linear ball bearing with a steel housing. Used in conjunction with a precision shaft to achieve high-precision, low-friction linear reciprocating motion.

Nomenclature Interpretation:

Key Feature: Outer layer is a robust steel sleeve, while the inner assembly consists of a plastic cage and steel balls.

Three-Layer Structure:

Working Principle:

The steel balls roll freely within the pockets of the cage. As the bearing moves along the shaft, the balls roll between the shaft surface and the cage.

Non-Recirculating Design: Unlike ball screws or linear guides, the balls in SCS do not recirculate infinitely through a loop. Instead, they perform short-range reciprocating rolling within the finite length of the bearing. Therefore, its stroke is not limited by its own length, but its friction and life characteristics differ from recirculating types.

Standard Features:

| Feature | SCS (Steel Sleeve Type) | SC (Aluminum Housing Type) | LM/UU (Most Universal Type) |

| Housing Material | Carbon steel, often zinc or nickel plated. | Aluminum alloy, lightweight. | Typically high-quality bearing steel (GCr15), through-hardened, extremely high hardness. |

| Core Characteristics | Balance of rigidity and cost. Robust and durable. | Extreme lightweight, used in weight-sensitive equipment. | High-performance standard. Best overall performance in load, rigidity, and precision. The most premium and universal standard type. |

| Rigidity | High. | Relatively low, prone to deformation. | Highest. |

| Weight | Relatively heavy. | Lightest. | Heavy. |

| Load Capacity | Relatively high. | Relatively low. | Highest. |

| Price | Medium, high cost-effectiveness. | Usually lowest (aluminum is inexpensive). | Highest. |

| Typical Applications | General industrial automation, medium-load equipment. | Lightweight robots, 3D printers, measuring instruments. | High-precision machine tool accessories, precision automation, heavy-duty guidance. |

Due to its robust and balanced characteristics, SCS is suitable for a wide range of industrial-grade scenarios:

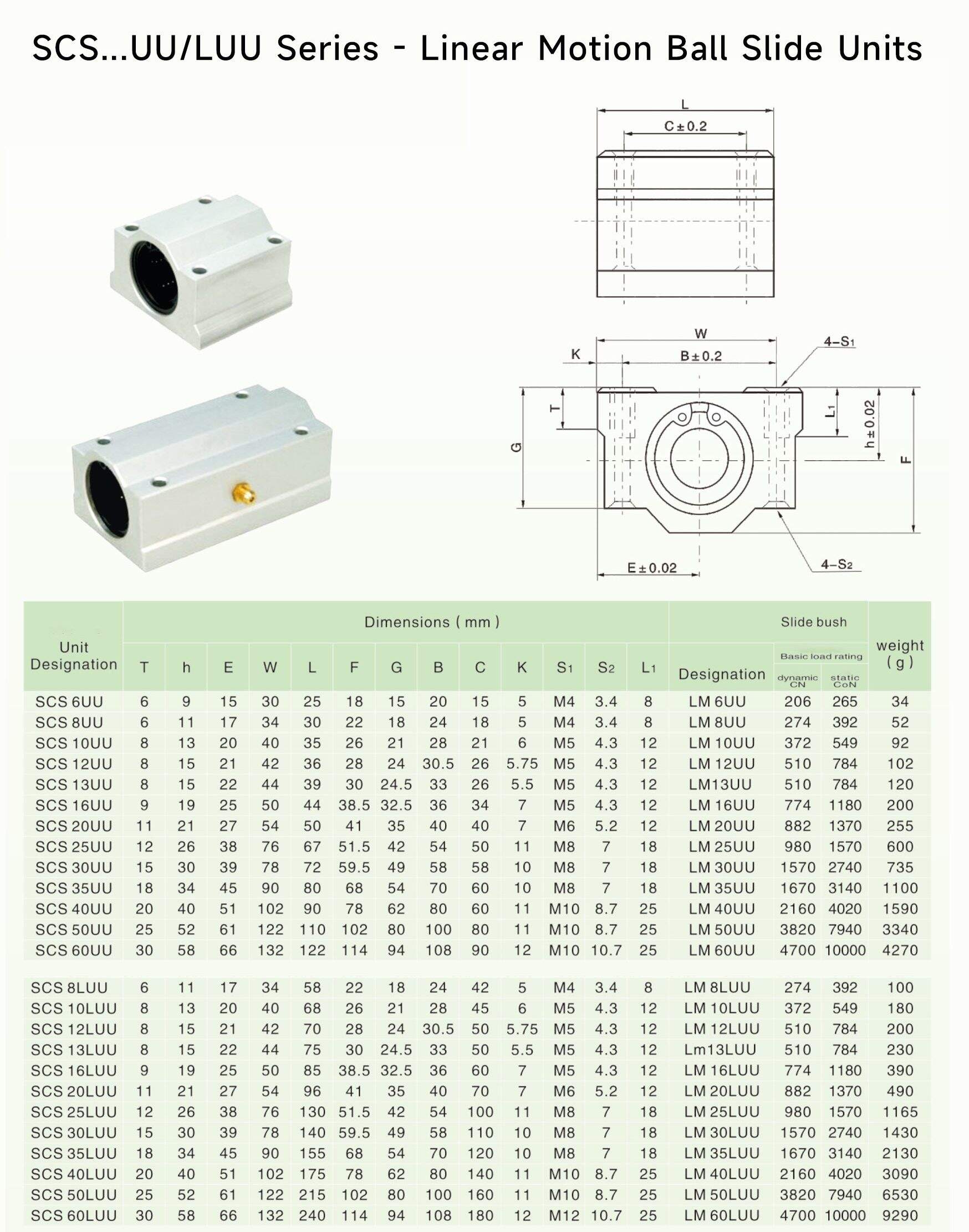

Determine Bore Diameter: Based on load and rigidity, select the shaft diameter (d). The SCS bore diameter must match it (with a small clearance).

Determine Outer Diameter: Based on installation space and support block model, select the outer diameter (D). It must match the bore of the support block (SHF/SK), typically with a transition fit.

Determine Length: The length (L) affects load capacity and stability. Longer bearings offer higher load capacity and better moment resistance.

The SCS linear bearing is the "mainstay" and "reliable workhorse" in the field of industrial linear motion. It may not possess the ultra-high rigidity and precision of linear guides, but its simple structure, robust durability, controllable cost, and standard installation make it the most cost-effective and reliable choice for a vast number of general automation applications where performance requirements are "good enough." Choosing SCS means selecting a mature, economical, and easy-to-maintain basic solution for linear guidance in equipment.