I. Core Structural Features (Directly Related to the MGN Naming)

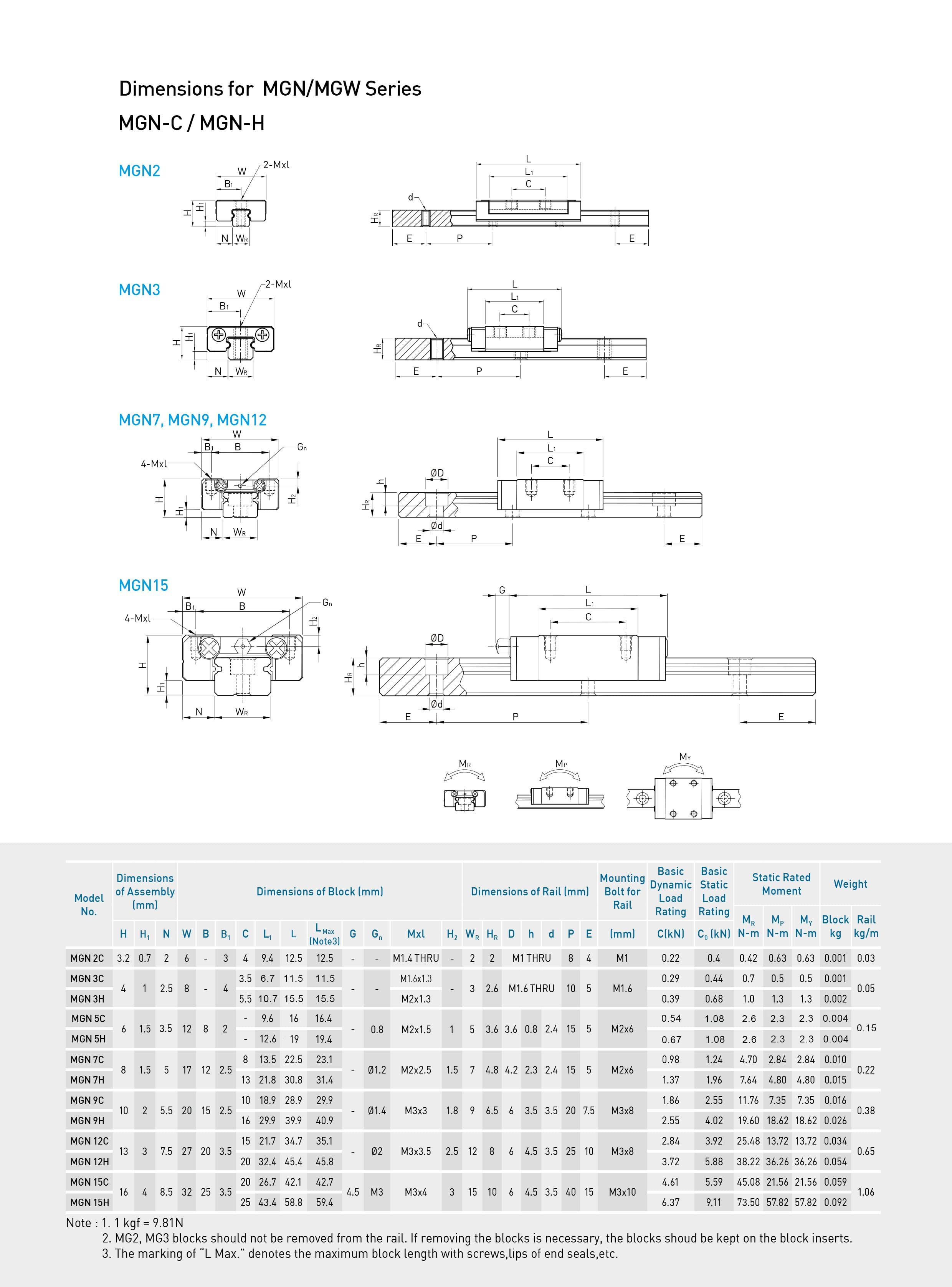

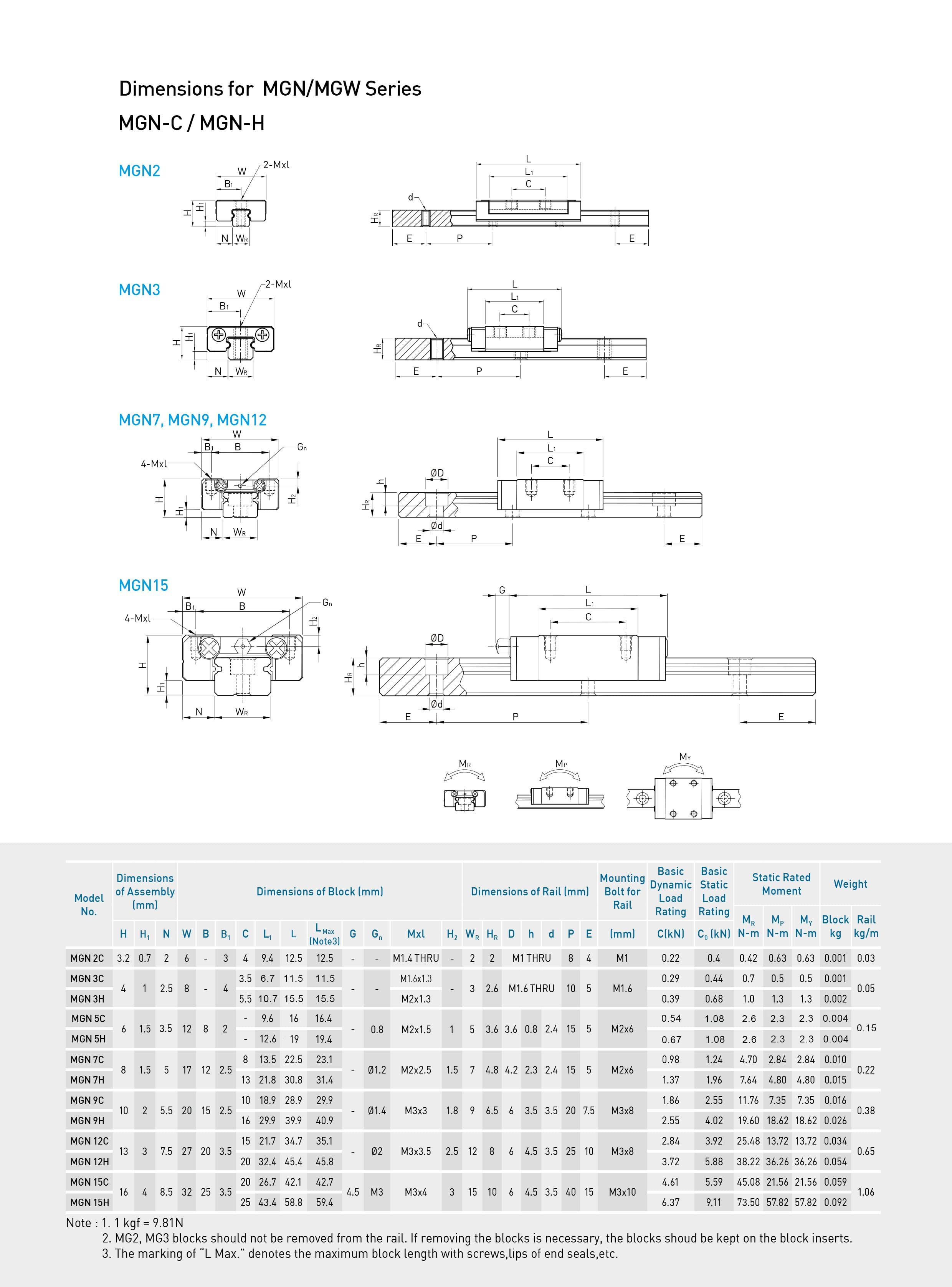

- M: Miniature – Represents its compact size, with small rail width and block height. Common specifications include MGN3, MGN5, MGN7, MGN9, MGN12, and MGN15 (the number indicates the rail width in millimeters).

- G: Ball – The rolling elements are precision steel balls, enabling low-friction, high-precision motion.

- N: Square (or Non-Separating) Block – This is its most distinctive visual feature. The block is an integrated square unit that wraps around the rail, making the structure highly compact.

II. Core Features and Advantages

High Rigidity & Equal Load Capacity in Four Directions

- The MGN guide block employs a two-point contact or four-row ball design, with balls symmetrically distributed inside the block.

- This allows it to withstand loads from all four directions (radial, reverse radial, and lateral), providing excellent resistance to torque and overturning moments. This is crucial for applications with limited space but requiring stable support.

High Precision and Smoothness

- As a precision-grade guide, it easily achieves different accuracy levels such as Normal (N), High (H), and Precision (P).

- The balls move through a precision circulation path, ensuring extremely smooth motion with minimal and consistent friction. This enables micron-level feed without crawling.

Compact Design and High Space Utilization

- With low height and narrow width, it is ideal for extremely space-constrained, slim, and miniaturized equipment.

- The integrated design of the block and rail eliminates the need for complex alignment and additional fixation during installation, saving design space and assembly time.

Easy Installation

- Compared to larger or separable guides, MGN installation is relatively straightforward. Typically, only the flatness and parallelism of the mounting reference surface need to be ensured. After fixing the rail, the block can be slid into place or secured via mounting holes.

- As an integrated block, users neither need nor can adjust the preload themselves. The preload is set by the manufacturer according to the model (e.g., light preload, medium preload).

High Speed and Low Noise

- The optimized design of the ball circulation system allows it to adapt to high operating speeds.

- With proper lubrication and load, it operates with low noise, making it suitable for applications requiring quiet operation.

Long Life and High Reliability

- Made from high-quality steel and heat-treated (e.g., rail high-frequency quenching), the raceway has high hardness and excellent wear resistance.

- Effective sealing design: The block is typically equipped with wipers and end seals at both ends and the bottom, along with an internal grease retention structure. This effectively prevents dust and chips from entering, maintains lubrication, and extends service life.

III. Comparison with Other Types of Guides (Highlighting Its Uniqueness)

Similar but Different MGN Guides:

- MGN: The standard form of miniature guides, with an integrated block, offering the most compact design.

- MGN: The wide version of miniature guides. The block is wider and longer than the same-sized MGN, providing higher rigidity and greater load capacity, though occupying slightly more space. Often used in precision instruments requiring higher stability.

Comparison with SBR and Other Round Shaft Linear Bearings:

- MGN: Surpasses them comprehensively in load capacity, rigidity, precision, service life, and smooth operation. SBR involves the of a shaft and bearing sleeve, which is surface contact, resulting in lower precision and rigidity.

Comparison with Large Roller Guides:

- MGN: Much smaller in size and load capacity but offers higher precision, lower friction, and a lower price. Roller guides are known for ultra-high rigidity and heavy-load capacity, used in large machine tools.

IV. Typical Application Fields

MGN guides, due to their "small but strong", are widely used in fields with stringent space and precision requirements:

- Semiconductor and Electronic Manufacturing Equipment: Chip machines, die bonders, SMT pick-and-place machines, PCB drilling machines.

- Precision Measurement and Inspection Equipment: CMMs, video measuring instruments, laser scanners.

- Medical Devices and Laboratory Automation: DNA sequencers, sampling robots, microscope stages.

- Optical and Photoelectric Equipment: Fiber alignment platforms, laser processing heads, lens positioning devices.

- High-End 3D Printers: Core X-Y-Z axis positioning, especially in Delta-type and CoreXY structures.

- Small Precision Machine Tools: Desktop CNC milling machines, engravers, feed axes of precision grinding machines.

V. Selection and Usage Considerations

- Specification Selection: Choose the appropriate specification (e.g., MGN12) based on load (force and moment), speed, accuracy requirements, and installation space.

- Accuracy Grade: Select Normal (N) or Precision (P) based on equipment positioning accuracy requirements.

- Preload Grade: Standard preload is typically light preload (C0). If high rigidity is required with minimal vibration and shock, heavy preload can be chosen, but it increases friction and heat generation.

- Mounting Reference: The flatness and parallelism of the mounting surface are fundamental to achieving the guide's performance and must be strictly ensured.

- Lubrication and Maintenance: Use specified grease or lubricating oil and regularly replenish lubrication via the block's oil nipples.

The core value of MGN linear guides lies in achieving high rigidity, high precision, and four-direction load capacity comparable to larger guides within an extremely compact, miniature size. They serve as the "skeleton" and "tendons" for modern precision instruments and small automation equipment to achieve high-performance linear motion. They are key foundational components driving the miniaturization, precision, and high performance of equipment.