In the ever-evolving landscape of industrial automation, linear guides have emerged as the cornerstone of precision motion control. These mechanical systems, often referred to as linear rails or profiled rail systems, are engineered to deliver unparalleled accuracy, reliability, and efficiency in applications ranging from CNC machining to medical robotics. As a mechanical engineer with over two decades of experience in high-precision automation, I have witnessed firsthand how linear guides transcend their role as mere components to become the backbone of deterministic motion in advanced manufacturing.

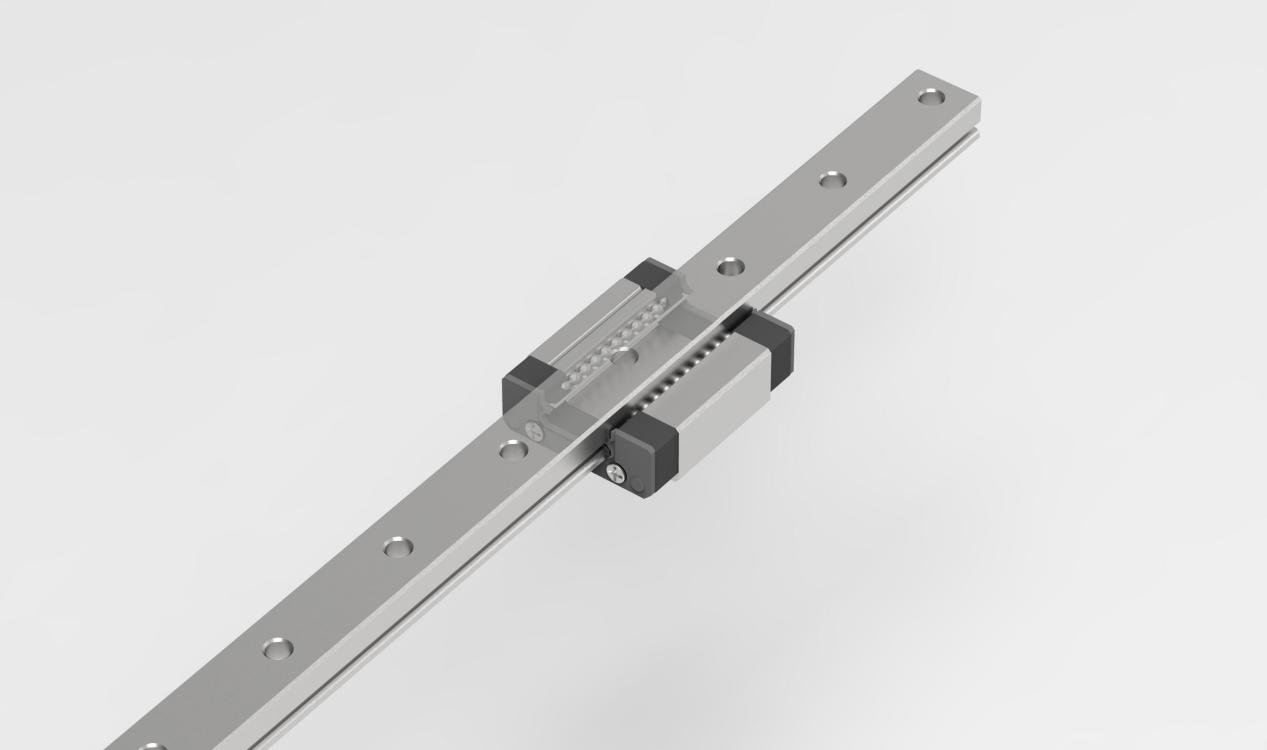

A linear guide system consists of two primary components: a hardened steel rail and a carriage (or slider) that houses recirculating rolling elements—typically balls or rollers. The interplay between these elements is critical: the rolling elements traverse precision-ground raceways, converting sliding friction into rolling friction. This design achieves friction coefficients as low as 0.001–0.003, enabling smooth, repeatable motion even under heavy loads.

Unlike traditional bushings or plain bearings, linear guides offer six degrees of constrained motion control. They resist not only vertical and horizontal forces but also moment loads (pitching, yawing, and rolling torques). This capability is indispensable in multi-axis CNC machines, semiconductor handlers, and robotic arms, where even minor deviations can lead to catastrophic failures in precision-critical operations.

The performance of a linear guide is governed by three pillars: load capacity, rigidity, and life expectancy. Dynamic load ratings (C) predict fatigue life under cyclic loading, while static ratings (C₀) ensure safety against permanent deformation during shock or standstill. A critical step often overlooked in preliminary designs is calculating the equivalent load (Pₑ) by vectorially combining radial, axial, and moment forces. Neglecting this step can lead to premature failure in high-stress environments.

Life estimation follows the ISO 14728 standard:

This model assumes proper lubrication, alignment within ±0.01 mm/m, and contamination control. In real-world applications, neglecting these factors can reduce actual life by up to 90%, underscoring the importance of meticulous system design.

The choice of materials directly impacts performance and longevity. Rails are typically crafted from through-hardened alloy steel (e.g., SUJ2 or equivalent), achieving surface hardness of HRC 58–64. Carriages incorporate wear-resistant cages and seals rated for IP54 or higher to withstand harsh environments. For corrosive settings, stainless steel variants (e.g., AISI 440C) or specialized coatings like black oxide or diamond-like carbon (DLC) are employed without compromising dimensional stability.

In aerospace and semiconductor manufacturing, where cleanliness is paramount, ceramic-coated rails and sealed ball bearings are preferred to minimize particulate contamination. These material innovations ensure that linear guides maintain sub-micron accuracy in ultra-cleanrooms, where even a single particle can disrupt nanoscale processes.

Installation precision is non-negotiable. Even micron-level misalignment induces edge loading, accelerates wear, and compromises repeatability. Best practices include:

Preload selection (light, medium, or heavy) fine-tunes the trade-off between rigidity and drag torque. For ultra-precision stages (e.g., in metrology or laser cutting), zero-backlash preloaded pairs are standard to eliminate play and ensure sub-micron positioning accuracy.

Linear guides are indispensable in sectors where precision is non-negotiable:

For example, in additive manufacturing (3D printing), linear guides ensure layer consistency by maintaining precise Z-axis movement. In pharmaceutical automation, they enable high-speed, sterile packaging with minimal vibration.

At [Your Company Name], we specialize in delivering industrial-grade linear guides that combine innovation with proven reliability. Here’s what sets us apart:

Our rails are manufactured using high-carbon alloy steels and heat-treated surfaces to enhance durability. With tolerances as tight as ±0.001 mm, they meet international standards like ISO 14721 and DIN 7987.

With five strategically located overseas warehouses, we reduce lead times and ensure cost-effective logistics. Our 24/7 technical support team is available to assist with product selection, installation, and troubleshooting.

We offer end-to-end customization services, from prototyping to mass production. Whether you need a custom rail profile, a specialized lubrication system, or corrosion-resistant coatings, our engineers work closely with you to meet exact specifications.

Our high-temperature linear guides operate reliably at up to 250°C, while IP67-rated models thrive in wet or dusty environments. For cleanroom applications, we provide ultra-low particulate emission variants.

A leading automotive manufacturer recently upgraded its robotic assembly line with our high-temperature linear guides. Designed to operate at 250°C, these guides improved production efficiency by 30% and reduced maintenance costs by 40%. This success story highlights how the right linear guide can transform industrial operations.