HGH Linear Guides typically refer to heavy-load ball linear guides. Unlike the previously mentioned miniature (MGN/MGW) guides, the HGH series belongs to standard-sized, high-load, industrial-grade guides, widely used in medium to large industrial equipment.

Positioning: Standard industrial-grade heavy-load guides. It is the preferred standard configuration for most medium to large automation equipment and machine tools.

Common Interpretation of Naming:

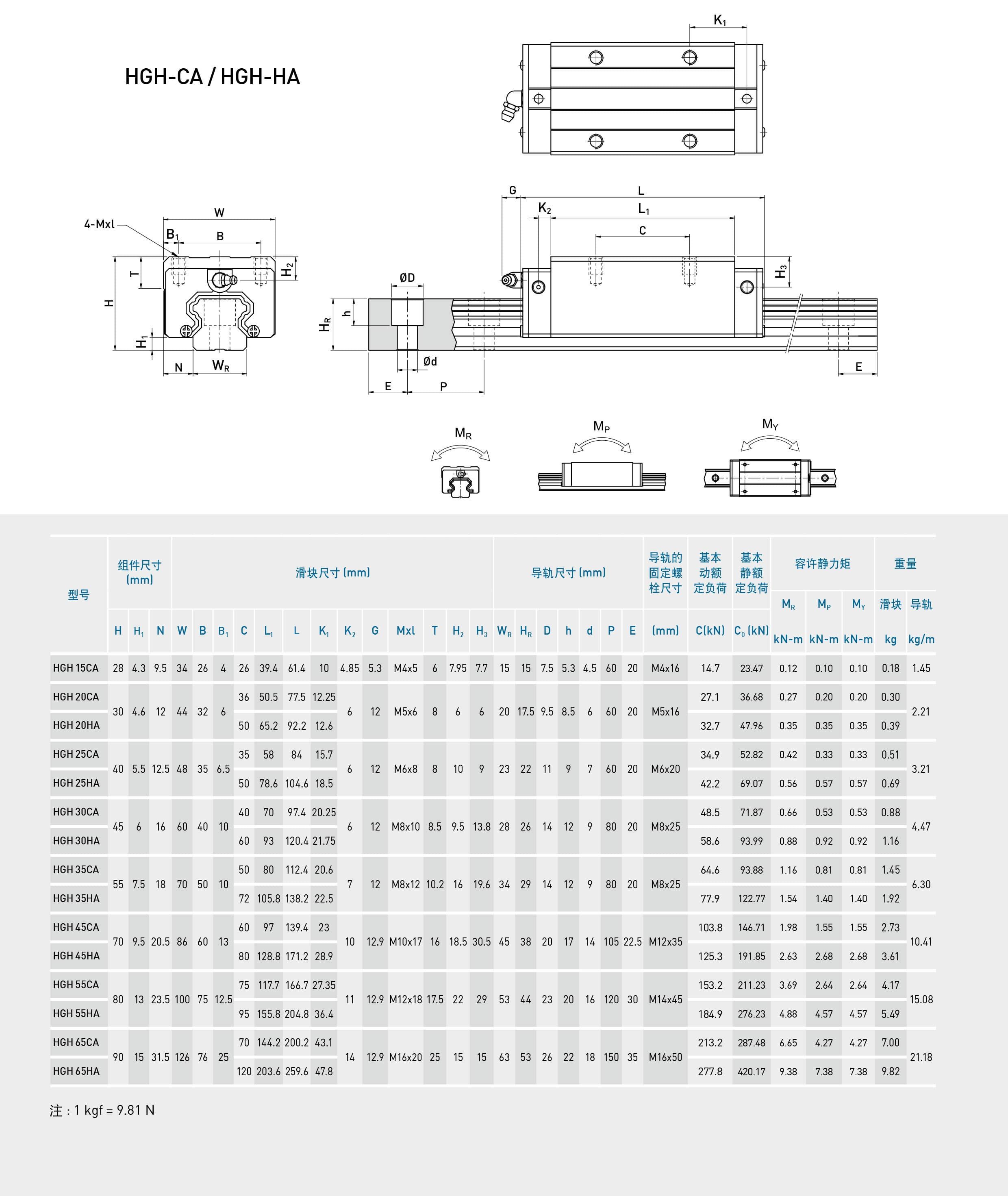

Common Specifications: Identified by rail width (mm), such as HGH15, HGH20, HGH25, HGH30, HGH35, HGH45, etc. Larger numbers indicate larger size and higher load capacity.

Classic "Square Equal-Section" Ball Rail Design:

The rail cross-section features symmetrical Gothic arch or circular groove shapes. This design enables the steel balls to form four-point or two-point contact with the raceways.

Core Advantage:Achieves high load capacity and high rigidity in all four directions (up, down, left, right). This is the key reason the HGH series has become an industrial standard.

Ball Recirculation System:

- The internal structure of the carriage is mature and reliable, with balls circulating smoothly through reversers in the end caps. The design focuses on high load capacity, long service life, and high reliability, rather than extreme miniaturization.

Carriage and Rail Combination:

- The carriage is a standard rectangular block with a separable design, meaning the carriage can be detached from the rail for easy installation and maintenance.

- Available in various carriage lengths (standard, extended, super-long). Longer lengths provide higher load capacity and rigidity.

Exceptional High Load Capacity:

- Thanks to larger steel ball sizes, multi-row recirculation designs, and reinforced structures, the rated static and dynamic loads are very high, making it an ideal choice for heavy-duty equipment transmission.

Ultra-High Rigidity:

- The large contact area between the carriage and rail, combined with the four-point contact design, provides excellent radial, reverse-radial, and lateral rigidity. This effectively resists vibration and impact, ensuring machining or motion accuracy.

High Precision and Smoothness:

- Available in multiple accuracy grades, from ordinary grade (N) to ultra-precision grade (UP), meeting diverse needs from general automation to high-precision machine tools.

- Smooth motion with a small and constant friction coefficient enables high-precision positioning without crawling.

Excellent Durability and Long Service Life:

- Made of high-quality alloy steel, with raceways hardened by high-frequency quenching or carburizing. The surface hardness is extremely high (HRC 58-62), offering excellent wear resistance.

- The theoretical life calculation formula (L10 life) is mature, ensuring extremely long service life when used correctly.

High Reliability and Environmental Adaptability:

- Comprehensive sealing system: The carriage is equipped with multiple sealing gaskets (scrapers) and end dust covers at both ends and the bottom, effectively preventing dust, debris, and liquids from entering.

- Standard carriages typically integrate lubrication channels and grease fittings for easy periodic maintenance and extended service life.

Installation Flexibility (Compared to Miniature Guides):

- Since the carriage and rail are separable, installation can be performed using the "horizontal pressure method" or "top-loading method," facilitating installation in confined spaces or different assembly scenarios.

- Professional installation and alignment are required to ensure parallelism and flatness between rails, thereby achieving optimal performance.

Characteristic |

HGH (Standard Heavy Load) |

MGN/MGW (Miniature) |

Size & Load Capacity |

Larger size, extremely high load capacity, used for medium to large equipment. |

Miniature size, relatively small load capacity, used for small, precision equipment. |

Application Positioning |

Industrial workhorse, strong versatility. CNC machine tools, automated production lines. |

Precision instruments, space is paramount. Semiconductor, optics, small-scale automation. |

Rigidity |

Ultra-high rigidity, robust structure, strong vibration resistance. |

High rigidity (relative to its size), but absolute load-bearing and moment resistance capabilities are limited. |

Installation |

Requires professional installation and adjustment, separable design. |

Relatively simple installation, integrated carriage block, high demands on mounting surface but simple steps. |

Price |

Higher unit price, but due to its high load capacity, offers good cost-effectiveness in large equipment. |

Lower unit price, but multiple units may be required in large equipment, potentially leading to higher total cost. |

Due to its reliability and high performance, HGH is regarded as the "universal skeleton" of the industrial field, widely applied in:

- Load and Life Calculation: Loads must be calculated based on actual operating conditions (force, moment, speed, stroke), and service life (L10 life) should be verified. This is fundamental to the selection process.

- Accuracy Grade Selection: Choose the appropriate accuracy grade according to equipment positioning requirements. For ordinary machine tools, H or P grades may suffice, while high-precision machine tools require grades above P.

- Preload Grade Selection:

- Installation Benchmark is Critical: The flatness, parallelism, and surface roughness of the mounting surface are vital to the final performance of HGH guides. Professional tools and methods must be used for installation and alignment.

- Lubrication and Maintenance: Strictly adhere to the specified lubrication intervals and grease types. Proper sealing and lubrication are essential for ensuring long service life.

HGH linear guides represent the mature, reliable, and high-performance standard of industrial-grade ball linear guides. Their core value lies in the classic yet robust four-point contact design, which achieves comprehensive high load capacity, high rigidity, and high precision within a standard size, meeting the stringent demands of most medium to heavy industrial equipment. Choosing HGH means selecting a solid, reliable, and time-tested industrial foundation for the core motion system of your equipment.