These three series are important variants of the standard LM (Linear Motion) bearings, primarily differing in the shape and mounting method of the outer ring to meet diverse mechanical design requirements.

Core Commonality:

Their internal structure (cage, steel balls, seals) is essentially identical to that of standard LM/UU bearings of the same size, offering the same inner diameter, precision, and load capacity. The differences lie entirely in the housing (outer ring).

Positioning: Square flange-mounted linear bearings. They integrate the bearing body and a square mounting flange into a single unit.

Structural Features:

Core Advantages and Applications:

Typical Applications: Ideal for scenarios requiring direct installation on flat or thick plates, such as custom-made small equipment, experimental benches, space-constrained mechanisms, or designs aiming for simplicity. A popular choice for DIY and light industrial applications.

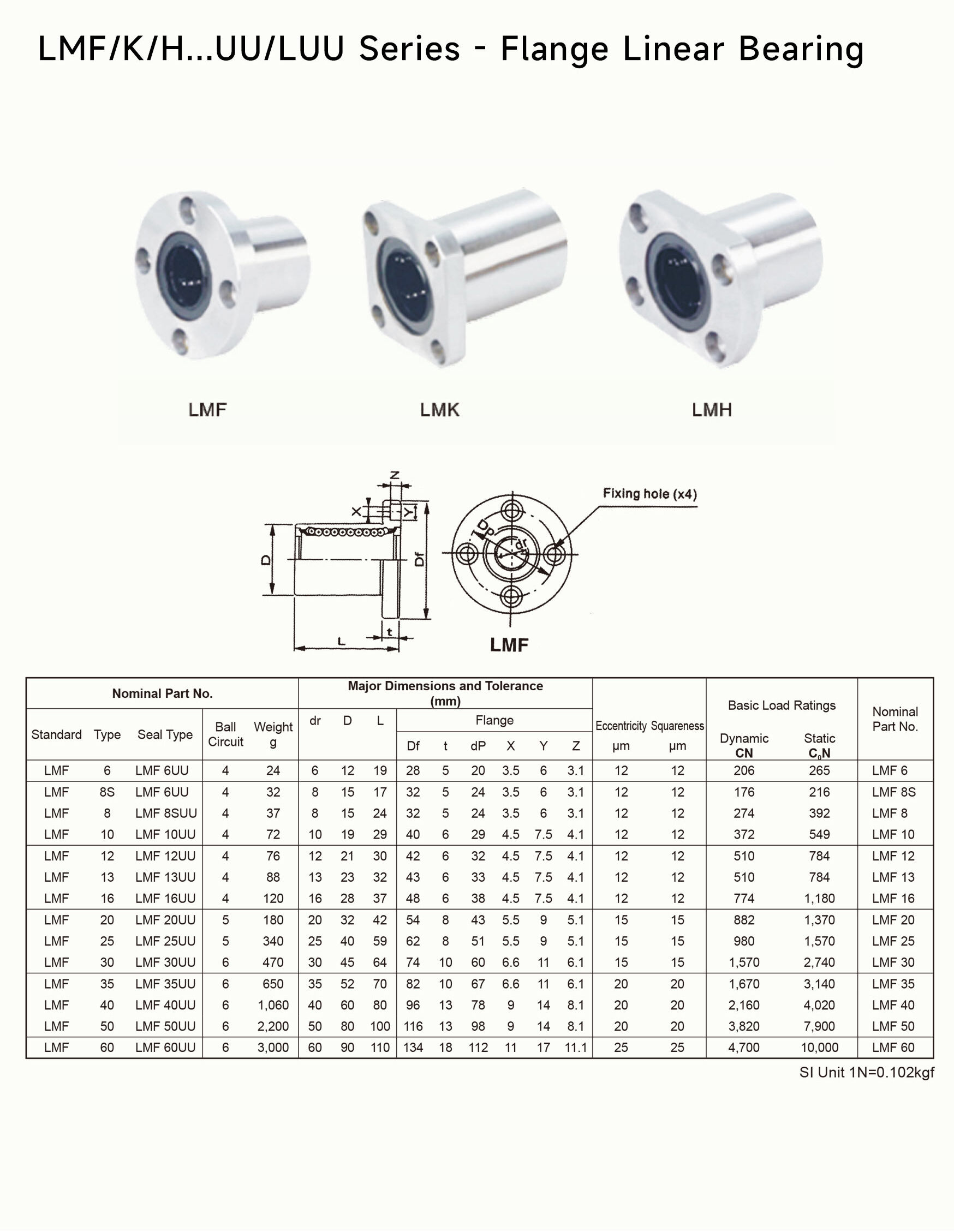

Positioning: Round flange-mounted linear bearings.

Structural Features:

Core Advantages and Applications:

Positioning: Threaded stud/bushing-type linear bearings. This is a unique and highly useful design.

Structural Features:

Core Advantages and Applications:

Typical Applications: Scenarios demanding high installation precision and adjustability, such as precision optical adjustment mounts, dual-guide systems requiring parallelism fine-tuning, or thin-walled structures where flanges or support blocks cannot be used.

Characteristic |

LMK (Square Flange) |

LMF (Round Flange) |

LMH (Threaded Stud) |

Standard LM + SHF/SK Support Block |

Mounting Method |

Direct screw mounting via flange |

Direct screw mounting via flange |

Threaded screwing into place |

Bearing first inserted into support block, then block is fixed |

Core Advantage |

Simple installation, fewer parts, high rigidity. |

Flexible mounting, saves radial space. |

Position is finely adjustable, allows rear mounting, flexible. |

Most versatile and standard. Support blocks can be split-type (SHF), offering excellent maintenance convenience. |

Mounting Complexity |

Simplest (one-step). |

Simple. |

Moderate (requires ensuring threaded fit). |

Most complex (two-step: insert bearing into block, then mount block). |

Adjustability |

Non-adjustable after fixing. |

Angle can be rotated before fixing. |

Axial position can be precisely fine-tuned. |

Achieved by adjusting the support block position, but it is more troublesome. |

Moment Resistance |

Strong (square flange resists torsion). |

Moderate. |

Weak (relies on threads for torsion resistance). |

Strongest (support block has large flange, good force distribution). |

Maintenance Convenience |

Poor (requires complete disassembly). |

Poor. |

Moderate (can be unscrewed). |

Best (SHF type allows opening the cover to replace the bearing without shaft removal). |

Application Scenario |

Direct mounting on flat plates, sufficient space, seeking simplicity. |

Compact space, requires angle adjustment. |

Requires fine-tuning, thin-wall mounting, special structures. |

Most industrial equipment, prioritizing reliability and maintainability. |

Cost Consideration |

High unit cost, but saves on support block. |

High unit cost, but saves on support block. |

High unit cost. |

LM bearing cost is low, but total cost with support block may be comparable or slightly lower. |

Prioritize Standard LM + SHF Support Blocks: For serious industrial designs, projects requiring maintenance, or designs not yet finalized, this is the most recommended, flexible, and reliable solution. The separable design of SHF is a significant advantage.

When to Choose LMK/LMF:

When to Choose LMH:

General Considerations:

Regardless of the model, always pair with high-precision hard-chrome linear shafts.

Ensure loads pass primarily through the bearing center to avoid overturning moments.

Pay attention to lubrication; flange types (LMK/LMF) may be less convenient to lubricate than standard LM bearings with grease fittings.

The LMK, LMF, and LMH series are intelligent extensions of standard linear bearing applications. By modifying the outer ring form, they integrate bearing functionality with mounting solutions, offering optimized options for specific scenarios.

LMK/LMF are "designed for quick installation," trading integration for assembly efficiency.

LMH is "designed for flexible adjustment and special mounting," offering unparalleled tuning flexibility through threaded connections.

However, this integration sacrifices the maintainability and design flexibility of the standard LM + separable support block (SHF) solution. Therefore, during selection, it is crucial to prioritize the entire process—installation, maintenance, and adjustment—rather than focusing solely on individual component characteristics. For most industrial applications, the modular standard solution remains the most robust choice in the long run.