I. Problem Diagnosis: Bottleneck of the traditional cylinder System • Insufficient positioning accuracy: When the cylinder is directly driven, the label position deviates by ±1.5mm, resulting in approximately 23,000 products requiring man...

• Insufficient positioning accuracy: When the cylinder is directly driven, the label position deviates by ±1.5mm, resulting in approximately 23,000 products requiring manual re-inspection every day

• Poor stability: The lateral force on the piston rod causes the sealing parts to be damaged every month, and the unplanned downtime of the production line accounts for 15% of the total working hours

• Speed limitation: To avoid vibration, the labeling speed is restricted to 60 pieces per minute, which is only 70% of the designed production capacity

• The fundamental reason: Pure cylinder drive has two inherent flaws - the piston rod itself is not good at bearing radial loads; Reciprocating motion lacks a precise guiding mechanism.

1. Core design concept

"Let the cylinder focus on output and let the guide rail be responsible for guidance."

The cylinder only provides axial driving force, while all radial loads and precise positioning are borne by the guide rails

The "floating connection" structure is adopted: the cylinder and the slider are connected through an adaptive coupling to eliminate the installation parallelism error between them

2. Specific implementation

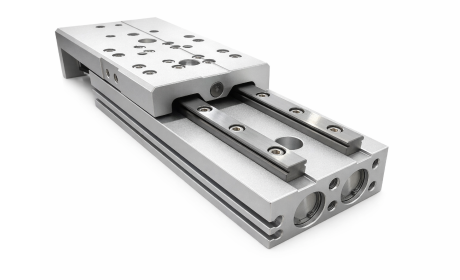

• Guide rail selection: MG series micro ball linear guides are selected, with a rated load of more than three times the thrust of the cylinder

• Layout optimization:

Horizontal axis: A single guide rail is arranged directly beneath the cylinder, forming a stable triangular support

Vertical axis: It adopts a symmetrical layout of double guide rails, completely eliminating the bending moment of the piston rod

• Intelligent control upgrade:

Magnetic grating scales are installed on the guide rail slider to achieve closed-loop position feedback

Through PLC programming, the cylinder switches to deceleration mode 50mm before the end of the stroke

Performance Metric |

Before Modification (Cylinder Only) |

After Modification (Cylinder + Guide Rail) |

Improvement Effect |

Labeling Position Repeatability Accuracy |

±1.2mm |

±0.05mm |

Accuracy improved by 24 times |

Maximum Stable Working Speed |

60 times/min |

95 times/min |

Speed increased by 58% |

Cylinder Seal Lifespan |

3 weeks |

9 months |

Lifespan extended by 13 times |

Product First-Pass Yield |

87.5% |

99.6% |

Defect rate reduced by 96% |

Daily Unplanned Downtime |

2.1 hours |

0.3 hours |

Reduced by 86% |

1. Direct economic benefits (calculated per year for a single production line)

Production increase benefits: Speed improvement + reduced downtime → Annual production increase of 1.42 million pieces, valued at approximately 2.13 million yuan

Cost savings

Reduce the annual maintenance cost of cylinders by 80,000 yuan

Reduce waste loss by 370,000 yuan per year

Return on investment: The total investment for the renovation is 150,000 yuan, and the payback period is only 2.3 months

2. Technical and management benefits

Technological breakthrough: For the first time, high-speed and precise labeling of high-viscosity irregular curved surface bottle bodies has been achieved

Maintenance innovation: Transform the cylinder from a "key vulnerable part" to a "long-lasting power unit", and shift the maintenance mode from emergency repair to prevention

The foundation of digitalization: It provides precise sports data for the subsequent introduction of the predictive maintenance system

This composite orientation scheme has formed standardized modules and has been successfully replicated in multiple scenarios:

• Packaging machinery: Box lid opening and closing mechanism → Solving the problem of cylinder hinge wear

• Electronic assembly: Chip pressing mechanism → Achieve pressure control within 0.02mm

• Logistics sorting: Push rod actuator → maintains zero failure for three years under a working condition of 6,000 times per day

• Functional decoupling thinking: A system where the cylinder and the guide rail perform their respective duties is more effective than the high-endization of a single component

• The full life cycle cost view: The initial investment in the guide rail is covered by a significant reduction in the maintenance cost of the cylinder

• Balance between standardization and flexibility: Through standardized guide rail interfaces, cylinders of different brands and specifications can be quickly adapted